Tech Talk

Forum home - Go back to Tech talk

|

Painful experience

|

|

|

« Back ·

1 ·

Next »

|

|

|

Return to top of page · Post #: 1 · Written at 11:23:57 AM on 11 December 2013.

|

|

|

|

Location: Blue Mountains, NSW

Member since 10 March 2013 Member #: 1312 Postcount: 401 |

|

I've just discovered an incredibly dangerous and painful activity, soldering in new IFT capacitors. Burnt finger tips from grabbing hot lugs to turn the IFT over. Not just once mind you but five times! Anyone watching would have wondered what I was up to, at one stage the soldering iron got thrown away. I felt like Homer Simpson every time. Doh! |

|

|

Return to top of page · Post #: 2 · Written at 2:21:15 PM on 11 December 2013.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

We all have our Doh! moments. |

|

|

Return to top of page · Post #: 3 · Written at 2:30:55 PM on 11 December 2013.

|

|

|

|

Location: Somewhere, USA

Member since 22 October 2013 Member #: 1437 Postcount: 896 |

|

Corrugated cardboard |

|

|

Return to top of page · Post #: 4 · Written at 2:55:12 PM on 11 December 2013.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6882 |

|

I have the el cheapo 'third hand' device which is fiddly but better than nothing and I sometimes use small alligator clips as temporary clamps inside chassis. I have been meaning to buy some insulated soldering tweezers for two-handed tasks and your post has reminded me to do that. |

|

|

Return to top of page · Post #: 5 · Written at 11:03:40 PM on 13 December 2013.

|

|

|

|

Location: Maclean, NSW

Member since 30 May 2008 Member #: 291 Postcount: 341 |

|

Hey Scraps, you are a slow learner being hit five times mate. |

|

|

Return to top of page · Post #: 6 · Written at 9:41:09 AM on 14 December 2013.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5595 |

|

Oh dear!.......Young people.... Haemostat's have been invented, not only can they work as a heat sink, they can lock onto a wire as you remove it, or re-solder; Get into small spaces and your fingers are nowhere near the heat |

|

|

Return to top of page · Post #: 7 · Written at 6:00:26 PM on 14 December 2013.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6882 |

|

Haemostats have been invented |

|

|

Return to top of page · Post #: 8 · Written at 12:21:29 AM on 15 December 2013.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5595 |

|

It also depends where the target is I do have a long pair of medical tweezers with a pin & Vee block. These have a second use as they are, because of the spike, ideal for removing jumpers on computer boards etc. |

|

|

Return to top of page · Post #: 9 · Written at 5:39:37 PM on 15 December 2013.

|

|

|

|

Location: Somewhere, USA

Member since 22 October 2013 Member #: 1437 Postcount: 896 |

|

How do you work under a chassis if it doesn't have the lips out the side to sit it in a jig? |

|

|

Return to top of page · Post #: 10 · Written at 5:55:02 PM on 15 December 2013.

|

|

|

|

Location: Blue Mountains, NSW

Member since 10 March 2013 Member #: 1312 Postcount: 401 |

|

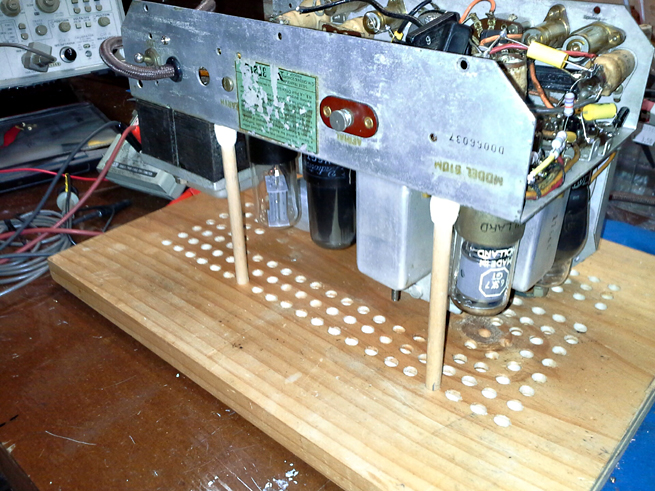

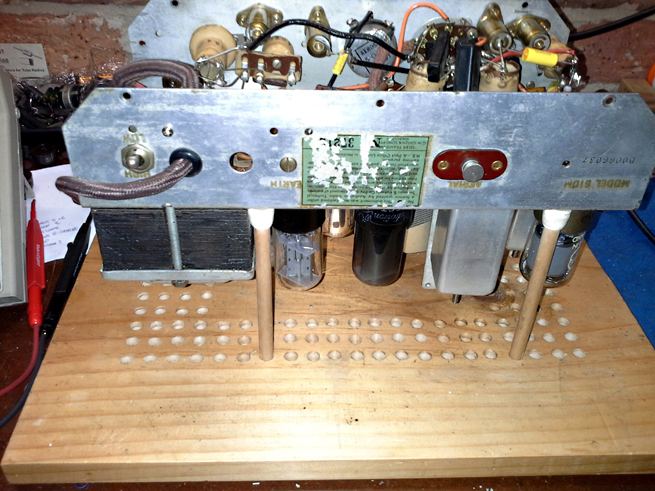

I'm sure everyone has a system but this is mine made up from a pine offcut, lots of holes and a selection of lengths of 8mm dowel with rubber tips. I drilled the slightly undersized holes in the drill press to ensure they were square and cut slots in the ends of the dowel to ensure a snug fit.   |

|

|

Return to top of page · Post #: 11 · Written at 8:06:59 PM on 15 December 2013.

|

|

|

|

Location: Somewhere, USA

Member since 22 October 2013 Member #: 1437 Postcount: 896 |

|

I think it's going to look like a bed of nails ? |

|

|

Return to top of page · Post #: 12 · Written at 10:13:39 PM on 15 December 2013.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

We had a thread on this topic a few months back - see |

|

|

Return to top of page · Post #: 13 · Written at 10:37:07 PM on 15 December 2013.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5595 |

|

HMV made a lot of their chasses with roll cages. I did have a bridge rail over the bench before I moved farm. |

|

|

« Back ·

1 ·

Next »

|

|

|

You need to be a member to post comments on this forum.

|

|

Sign In

Vintage Radio and Television is proudly brought to you by an era where things were built with pride and made to last.

DISCLAIMER: Valve radios and televisions contain voltages that can deliver lethal shocks. You should not attempt to work on a valve radio or other electrical appliances unless you know exactly what you are doing and have gained some experience with electronics and working around high voltages. The owner, administrators and staff of Vintage Radio & Television will accept no liability for any damage, injury or loss of life that comes as a result of your use or mis-use of information on this website. Please read our Safety Warning before using this website.

WARNING: Under no circumstances should you ever apply power to a vintage radio, television or other electrical appliance you have acquired without first having it checked and serviced by an experienced person. Also, at no time should any appliance be connected to an electricity supply if the power cord is damaged. If in doubt, do not apply power.

Shintara - Keepin' It Real · VileSilencer - Maintain The Rage