Tech Talk

Forum home - Go back to Tech talk

|

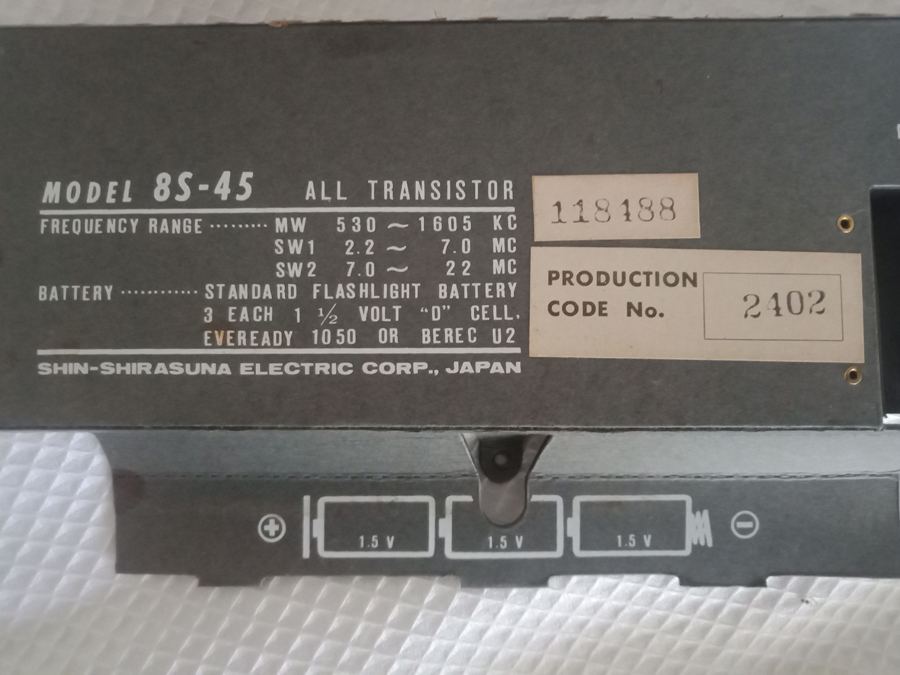

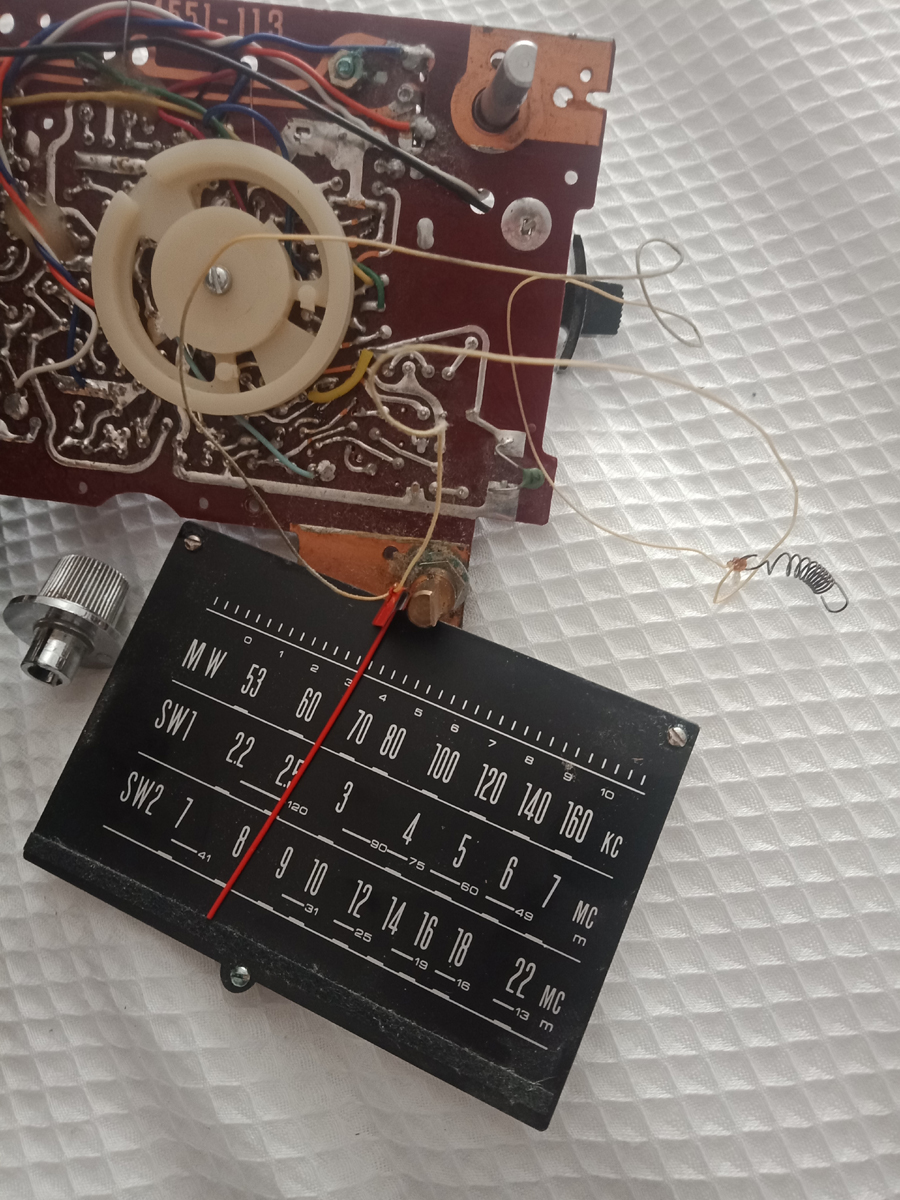

Silver Radio - Model 8S - 45 (All Transistor) MW / SW1 / SW2 - Threading Radio Tuner Dial & Volume Potentiometer

|

|

|

Return to top of page · Post #: 1 · Written at 3:35:58 PM on 8 May 2020.

|

|

|

|

Location: Hawthorn, VIC

Member since 8 May 2020 Member #: 2417 Postcount: 10 |

|

Hi All       |

|

|

Return to top of page · Post #: 2 · Written at 4:30:46 PM on 8 May 2020.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6902 |

|

Here's one local source of such a pot pot (interestingly with the switch mechanism exposed like yours): https://www.minikits.com.au/POT5K-16LOGA-SW |

|

|

Return to top of page · Post #: 3 · Written at 4:32:37 PM on 8 May 2020.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7577 |

|

Photos uploaded. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 4 · Written at 4:44:58 PM on 8 May 2020.

|

|

|

|

Location: Hawthorn, VIC

Member since 8 May 2020 Member #: 2417 Postcount: 10 |

|

Thanks GTC |

|

|

Return to top of page · Post #: 5 · Written at 4:50:40 PM on 8 May 2020.

|

|

|

|

Location: Hobart, TAS

Member since 31 July 2016 Member #: 1959 Postcount: 586 |

|

The chances are the switch is alright, and has just been bridged out. |

|

|

Return to top of page · Post #: 6 · Written at 4:51:25 PM on 8 May 2020.

|

|

|

|

Location: Hawthorn, VIC

Member since 8 May 2020 Member #: 2417 Postcount: 10 |

|

Yes I meant to say it has a D Shaft |

|

|

Return to top of page · Post #: 7 · Written at 4:57:51 PM on 8 May 2020.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6902 |

|

Yes it has a splined shaft |

|

|

Return to top of page · Post #: 8 · Written at 5:01:06 PM on 8 May 2020.

|

|

|

|

Location: Hawthorn, VIC

Member since 8 May 2020 Member #: 2417 Postcount: 10 |

|

Hi Johnny |

|

|

Return to top of page · Post #: 9 · Written at 5:10:13 PM on 8 May 2020.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6902 |

|

Because of the angle of the shot, photo #4 at first glance gives the impression that the switch has been bridged out, but photo #5 clearly shows a black and grey (or white) wire to each contact. |

|

|

Return to top of page · Post #: 10 · Written at 5:16:52 PM on 8 May 2020.

|

|

|

|

Location: Hobart, TAS

Member since 31 July 2016 Member #: 1959 Postcount: 586 |

|

Sorry yes on very close inspection switch is not bridged out. |

|

|

Return to top of page · Post #: 11 · Written at 5:28:37 PM on 8 May 2020.

|

|

|

|

Location: Hawthorn, VIC

Member since 8 May 2020 Member #: 2417 Postcount: 10 |

|

Thanks Johnny |

|

|

Return to top of page · Post #: 12 · Written at 5:32:54 PM on 8 May 2020.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6902 |

|

NA1012 looks OK. I use CRC brand. |

|

|

Return to top of page · Post #: 13 · Written at 7:17:28 PM on 8 May 2020.

|

|

|

|

Location: Hawthorn, VIC

Member since 8 May 2020 Member #: 2417 Postcount: 10 |

|

Thanks guys. |

|

|

Return to top of page · Post #: 14 · Written at 7:31:48 PM on 8 May 2020.

|

|

|

|

Location: Hobart, TAS

Member since 31 July 2016 Member #: 1959 Postcount: 586 |

|

The pot track is carbon, and after a lot of use or age there are lots of fine dry granules of carbon on the surface of the track. |

|

|

Return to top of page · Post #: 15 · Written at 7:36:51 PM on 8 May 2020.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6902 |

|

D5K appears to be the part number/category, maybe D shaft 5K ohms. |

|

|

You need to be a member to post comments on this forum.

|

|

Sign In

Vintage Radio and Television is proudly brought to you by an era where things were built with pride and made to last.

DISCLAIMER: Valve radios and televisions contain voltages that can deliver lethal shocks. You should not attempt to work on a valve radio or other electrical appliances unless you know exactly what you are doing and have gained some experience with electronics and working around high voltages. The owner, administrators and staff of Vintage Radio & Television will accept no liability for any damage, injury or loss of life that comes as a result of your use or mis-use of information on this website. Please read our Safety Warning before using this website.

WARNING: Under no circumstances should you ever apply power to a vintage radio, television or other electrical appliance you have acquired without first having it checked and serviced by an experienced person. Also, at no time should any appliance be connected to an electricity supply if the power cord is damaged. If in doubt, do not apply power.

Shintara - Keepin' It Real · VileSilencer - Maintain The Rage