Cabinet Repairs

Forum home - Go back to Cabinet Repairs

|

Casting replacement knobs

|

|

|

Return to top of page · Post #: 1 · Written at 6:18:47 PM on 12 July 2014.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

Anyone have tips on making a plastic or resin cast to replace a missing knob? |

|

|

Return to top of page · Post #: 2 · Written at 9:31:36 PM on 12 July 2014.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6911 |

|

I'll be interested in responses to your question, too. The idea of embedding a small sacrificial knob is a good idea as long as the moulding compound takes to it. |

|

|

Return to top of page · Post #: 3 · Written at 10:39:44 PM on 12 July 2014.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7591 |

|

I am told there are a few collectors that do make reproduction knobs. One even claims to make them from Bakelite, which I find a little hard to believe given the large and energy-intensive equipment required to make a mixture of Bakelite set correctly. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 4 · Written at 1:28:50 AM on 13 July 2014.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5668 |

|

There was some sort of rubbery stuff that once set you could roll off the original knob & then use it to make a few. That from and epoxy resin which was able to be pigment coloured. I think the resin was a 1:3 type one. |

|

|

Return to top of page · Post #: 5 · Written at 9:52:41 AM on 13 July 2014.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

I've seen clear casting compounds but they are sold in quantities more than I want and at some tens of dollars a pop. As usual I'm looking for a cheap DIY solution. |

|

|

Return to top of page · Post #: 6 · Written at 10:13:29 AM on 13 July 2014.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5668 |

|

There are hard compounds like "Knead it" and a few others that are used to repair pits in pump shafts etc. So Bunnings etc may not be the place to look. |

|

|

Return to top of page · Post #: 7 · Written at 11:18:58 AM on 13 July 2014.

|

|

|

|

Location: Blue Mountains, NSW

Member since 10 March 2013 Member #: 1312 Postcount: 401 |

|

I've been experimenting on and off for a while to get this right. As you mentioned the real moulding stuff is prohibitively expensive so I've been working with cheap stuff. |

|

|

Return to top of page · Post #: 8 · Written at 12:33:10 PM on 13 July 2014.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5668 |

|

Note I trained & worked as a textile dyer and also worked in polymer chemistry One of the best things that will not, in most cases, adversely effect the reactants are the pigments that are used for colourants in stuff like concrete. |

|

|

Return to top of page · Post #: 9 · Written at 5:50:56 PM on 13 July 2014.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

Lots of helpful points coming, unlike.. |

|

|

Return to top of page · Post #: 10 · Written at 6:21:23 PM on 13 July 2014.

|

|

|

|

Location: Blue Mountains, NSW

Member since 10 March 2013 Member #: 1312 Postcount: 401 |

|

If you need something crystal clear then the Craft Smart Liquid Gloss is perfect. It does form a layer of tiny bubbles on the surface as it cures but these are easily removed with a small blowtorch or hot air gun such as a gas soldering iron. It is very easy to mix and pour. The knobs I've made using this have a mirror like base but a slightly dull surface from the mould. When cured it's as clear as glass. |

|

|

Return to top of page · Post #: 11 · Written at 6:24:16 PM on 13 July 2014.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6911 |

|

Some YouTube clips and articles on the subject: |

|

|

Return to top of page · Post #: 12 · Written at 1:02:27 AM on 14 July 2014.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5668 |

|

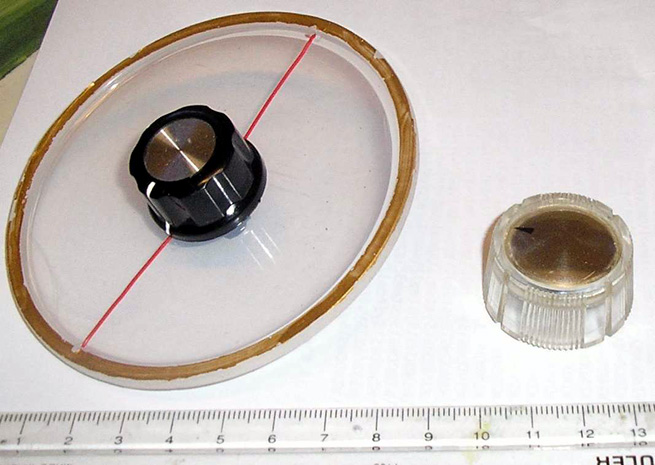

It may not help? But if you have a knob to copy, it may be an idea to post a photo. I am wondering if it can be made in one or, two parts with Perspex if its clear? |

|

|

Return to top of page · Post #: 13 · Written at 11:45:40 AM on 14 July 2014.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

I'm sending a photo as Marc suggests. |

|

|

Return to top of page · Post #: 14 · Written at 12:26:48 PM on 14 July 2014.

|

|

|

|

Location: Blue Mountains, NSW

Member since 10 March 2013 Member #: 1312 Postcount: 401 |

|

Can't wait to see pictures, the description sounds like something out of MacGyver |

|

|

Return to top of page · Post #: 15 · Written at 1:15:57 PM on 14 July 2014.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

I take "MacGyver" as a compliment!  Meanwhile checked some resin prices. Smallest quantity of Craft Smart Liquid Gloss seems to be $30 for 125ml x 2 (resin and hardener). Bunnings have this Diggers casting and embedding resin product for less than half that, though not sure how much the hardener costs. Anyone used that? I'll go out and have a sniff around. Maven |

|

|

You need to be a member to post comments on this forum.

|

|

Sign In

Vintage Radio and Television is proudly brought to you by an era where things were built with pride and made to last.

DISCLAIMER: Valve radios and televisions contain voltages that can deliver lethal shocks. You should not attempt to work on a valve radio or other electrical appliances unless you know exactly what you are doing and have gained some experience with electronics and working around high voltages. The owner, administrators and staff of Vintage Radio & Television will accept no liability for any damage, injury or loss of life that comes as a result of your use or mis-use of information on this website. Please read our Safety Warning before using this website.

WARNING: Under no circumstances should you ever apply power to a vintage radio, television or other electrical appliance you have acquired without first having it checked and serviced by an experienced person. Also, at no time should any appliance be connected to an electricity supply if the power cord is damaged. If in doubt, do not apply power.

Shintara - Keepin' It Real · VileSilencer - Maintain The Rage