Vintage Television

Forum home - Go back to Vintage Television

|

Kreisler 79-2/3 chassis

|

|

|

« Back ·

1 ·

Next »

|

|

|

Return to top of page · Post #: 1 · Written at 1:38:48 PM on 31 December 2015.

|

|

|

|

Location: Belrose, NSW

Member since 31 December 2015 Member #: 1844 Postcount: 2671 |

|

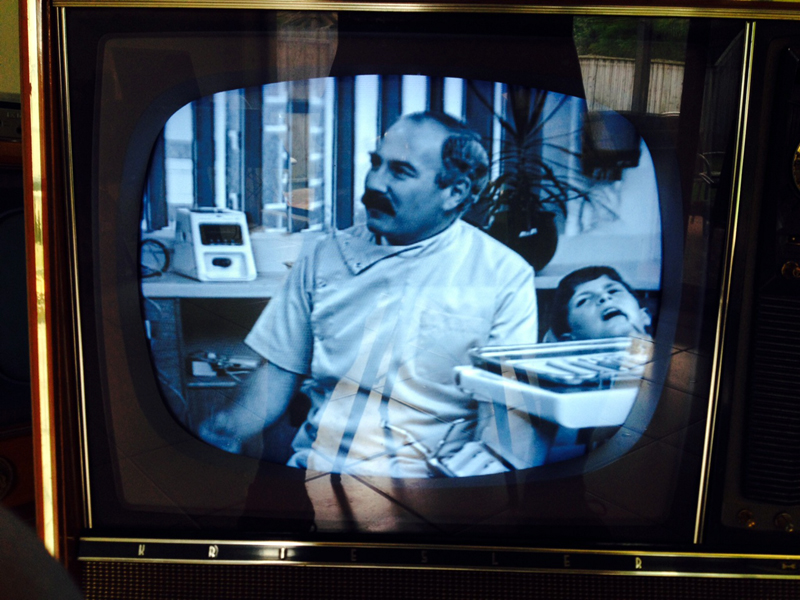

I'm new to this forum but I have a small vintage TV collection - Ekco TX275 portable, AWA 209C and now a Kriesler dating from mid 1959. Cabinet is original, without so much as a scratch. Going by the history card, in November 1970 the set received an overhaul including a new Philips CRT (not a regun, the warranty card is there) and partial recapping. So it looks good for restoration which I'm doing at the moment. I've re-formed the electrolytics and I'm just waiting on a 6AL3 to arrive. Used to be stock-in-trade, the 6AL3! Does anyone know why they always failed cracked glass after rain? |

|

|

Return to top of page · Post #: 2 · Written at 9:28:06 AM on 1 January 2016.

|

|

|

|

Location: Hill Top, NSW

Member since 18 September 2015 Member #: 1801 Postcount: 2232 |

|

Good luck with that. I have (or had, maybe) heaps of used 6AL3's. |

|

|

Return to top of page · Post #: 3 · Written at 5:36:45 PM on 1 January 2016.

|

|

|

|

Location: Belrose, NSW

Member since 31 December 2015 Member #: 1844 Postcount: 2671 |

|

Sorry guys. I just found the Kriesler schematic well out of sequence in the pdf. It's actually a 79-2 revision 3. |

|

|

Return to top of page · Post #: 4 · Written at 7:49:17 PM on 1 January 2016.

|

|

|

|

Location: Hill Top, NSW

Member since 18 September 2015 Member #: 1801 Postcount: 2232 |

|

If I'd known you wanted a 5AS4... I have quite a lot of used ones just taking up space here. |

|

|

Return to top of page · Post #: 5 · Written at 4:55:13 PM on 4 January 2016.

|

|

|

|

Location: Melbourne, VIC

Member since 20 September 2011 Member #: 1009 Postcount: 1260 |

|

There are 3 issues of the 79-2 chassis schematics. Issues 1 & 2 has a Philips AT7580 tuner with valves 6CW7 (V6) & 6BL8 (V7). Issue 3 , as mentioned, has the Philips NT3001 tuner with valves 6ES8 (V6) & 6BL8 (V7). In issues 2 & 3 the 1st video IF amp valve (V8) is a 6BY7 instead of a 6BX6. All versions use a 6R3 damper diode. |

|

|

Return to top of page · Post #: 6 · Written at 11:23:18 AM on 6 January 2016.

|

|

|

|

Location: Belrose, NSW

Member since 31 December 2015 Member #: 1844 Postcount: 2671 |

|

Thanks Monochrome. |

|

|

Return to top of page · Post #: 7 · Written at 12:17:04 PM on 6 January 2016.

|

|

|

|

Location: Melbourne, VIC

Member since 20 September 2011 Member #: 1009 Postcount: 1260 |

|

Your Future-line Console is a model 121-12A. It is the first of the 79-2 chassis using the NT3001 tuner. There is also a Future-line Console model 121-12AF with a 79-3 chassis and a 110 degree AW53-88 CRT. |

|

|

Return to top of page · Post #: 8 · Written at 8:50:17 PM on 7 January 2016.

|

|

|

|

Location: Belrose, NSW

Member since 31 December 2015 Member #: 1844 Postcount: 2671 |

|

Hi TV Collector |

|

|

Return to top of page · Post #: 9 · Written at 7:23:18 AM on 14 January 2016.

|

|

|

|

Location: Melbourne, VIC

Member since 20 September 2011 Member #: 1009 Postcount: 1260 |

|

Thanks for the Kriesler Magi-Matic user manual. |

|

|

Return to top of page · Post #: 10 · Written at 3:33:36 PM on 3 April 2016.

|

|

|

|

Location: Belrose, NSW

Member since 31 December 2015 Member #: 1844 Postcount: 2671 |

|

Hi All  |

|

|

Return to top of page · Post #: 11 · Written at 4:05:15 PM on 3 April 2016.

|

|

|

|

Location: Hill Top, NSW

Member since 18 September 2015 Member #: 1801 Postcount: 2232 |

|

You are extremely lucky you saw that fire before it could burn your house down. |

|

|

Return to top of page · Post #: 12 · Written at 7:48:12 PM on 3 April 2016.

|

|

|

|

Location: Belrose, NSW

Member since 31 December 2015 Member #: 1844 Postcount: 2671 |

|

Yeah, well I don't know about that, there wasn't enough flammable material for the fire to catch the cabinet even if it had got that far. Back in the day I saw lots of wax and paper EHT overwind fires (Rola and Precedent transformers come to mind) and the worst effect was a sooty EHT cage. You can see why all plastics used in electrical goods are supposed to contain fire retardants. And the ramifications for a manufacturer if their Chinese contractor decides to cut costs! |

|

|

Return to top of page · Post #: 13 · Written at 4:11:14 PM on 7 April 2016.

|

|

|

|

Location: Belrose, NSW

Member since 31 December 2015 Member #: 1844 Postcount: 2671 |

|

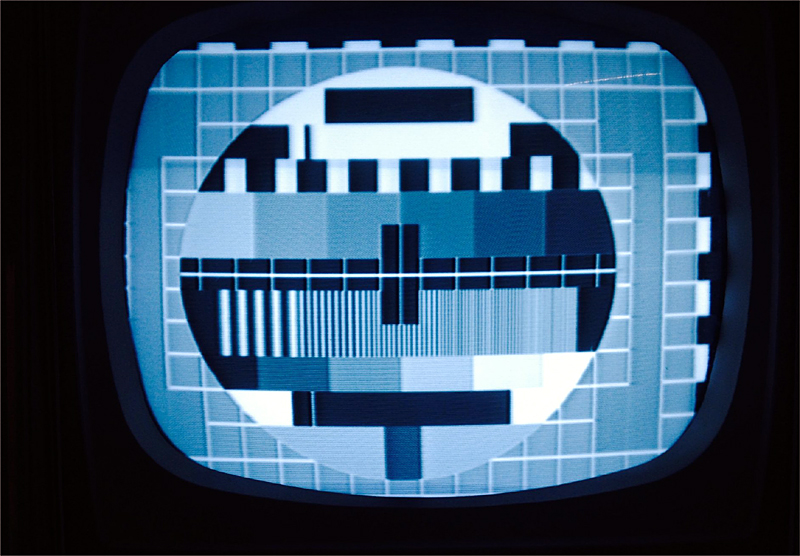

I've since been able to put up a test pattern on the TV.  |

|

|

Return to top of page · Post #: 14 · Written at 4:44:29 PM on 7 April 2016.

|

|

|

|

Location: Hill Top, NSW

Member since 18 September 2015 Member #: 1801 Postcount: 2232 |

|

An offset is caused by an incorrect amount of DC flowing through the scan coils (the yoke). Adjusting the AC characteristics (the line frequency) isn't the correct way to fix it. |

|

|

Return to top of page · Post #: 15 · Written at 9:06:34 AM on 8 April 2016.

|

|

|

|

Location: Belrose, NSW

Member since 31 December 2015 Member #: 1844 Postcount: 2671 |

|

Yes Rob but the hor shift issue in this case is caused by the positioning of the pic on the raster. The scan continues (scanning lines light the screen) beyond the edge of the mask. You can shift the picture about 20% with the front panel hor hold control before lock is lost. |

|

|

« Back ·

1 ·

Next »

|

|

|

You need to be a member to post comments on this forum.

|

|

Sign In

Vintage Radio and Television is proudly brought to you by an era where things were built with pride and made to last.

DISCLAIMER: Valve radios and televisions contain voltages that can deliver lethal shocks. You should not attempt to work on a valve radio or other electrical appliances unless you know exactly what you are doing and have gained some experience with electronics and working around high voltages. The owner, administrators and staff of Vintage Radio & Television will accept no liability for any damage, injury or loss of life that comes as a result of your use or mis-use of information on this website. Please read our Safety Warning before using this website.

WARNING: Under no circumstances should you ever apply power to a vintage radio, television or other electrical appliance you have acquired without first having it checked and serviced by an experienced person. Also, at no time should any appliance be connected to an electricity supply if the power cord is damaged. If in doubt, do not apply power.

Shintara - Keepin' It Real · VileSilencer - Maintain The Rage