Wanted and For Sale

Forum home - Go back to Wanted and for sale

|

Wanted - audio board for AWA B92 radiogram

|

|

|

Return to top of page · Post #: 16 · Written at 8:57:24 AM on 6 February 2018.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5687 |

|

The length of the drill and the amount protruding are part of the problem along with the hardening. "Case Hardening" was found to be a problem with car axles & not confined to them. |

|

|

Return to top of page · Post #: 17 · Written at 11:55:01 AM on 6 February 2018.

|

|

|

|

Location: Daylesford, VIC

Member since 13 January 2011 Member #: 809 Postcount: 326 |

|

OK, I'll have a go myself, and if I stuff it up I'll call on your expertise, Ian. I want to make my own boards anyway to finish a couple of Seventies Electronics Australia projects I've started. I've bought the old fashioned brown phenolic board already, might as well use it. |

|

|

Return to top of page · Post #: 18 · Written at 1:26:48 PM on 6 February 2018.

|

|

|

|

Location: Toongabbie, NSW

Member since 19 November 2015 Member #: 1828 Postcount: 1400 |

|

Good on you Sue, don't listen to those young whippersnappers, just centre punch the holes through the copy of the handbook, do the iron on from the printer or dalo pen outline act and etch the bloody thing. Done ! The centre punch marks will centre the drill no worries. |

|

|

Return to top of page · Post #: 19 · Written at 3:58:35 PM on 6 February 2018.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7611 |

|

There is nothing like splashing the dalo pens around and splilling ferric chloride around the kitchen and on your fingers ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 20 · Written at 9:43:09 PM on 6 February 2018.

|

|

|

|

Location: Adelaide, SA

Member since 27 February 2010 Member #: 630 Postcount: 398 |

|

Er... Didn't get a reply until too late. I am not able to look due to being out of the state. I will check in a week or so. I know I have fixed a couple of them in the past year and pretty sure a bloke I restore for trashed one of them and it will be in the parts buckets. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ Valve radios, They just don't make them like they used to |

|

|

Return to top of page · Post #: 21 · Written at 5:02:51 PM on 7 February 2018.

|

|

|

|

Location: Daylesford, VIC

Member since 13 January 2011 Member #: 809 Postcount: 326 |

|

OK, I'll hold off on making a board until you get back. |

|

|

Return to top of page · Post #: 22 · Written at 8:56:11 PM on 7 February 2018.

|

|

|

|

Location: Linton, VIC

Member since 30 December 2016 Member #: 2028 Postcount: 472 |

|

I got my chemistry set for Xmas in 1967 also. |

|

|

Return to top of page · Post #: 23 · Written at 2:29:10 PM on 9 February 2018.

|

|

|

|

Location: Daylesford, VIC

Member since 13 January 2011 Member #: 809 Postcount: 326 |

|

(Dried chips of the plant logwood produce a deep purple-red solution in water. It was used as an acid indicator - it turned brown when acidic, and it was also used for dyeing wool, which is why it's about the worst thing to spill on off-white wallpaper.) |

|

|

Return to top of page · Post #: 24 · Written at 7:55:28 PM on 9 February 2018.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5687 |

|

Chemistry can be fun. I started work in a Lab, trained as a textile dyer (more chemicals) & ended up spending several years with a big chemistry set, making Polymers, Resins, Wax emulsions & using lots of things like Strong acids & Bases, Oxidant's, Reducing agents, Flammables, Carcinogens & other very interesting things, some of which were actually pretty harmless. |

|

|

Return to top of page · Post #: 25 · Written at 10:37:21 PM on 9 February 2018.

|

|

|

|

Location: Linton, VIC

Member since 30 December 2016 Member #: 2028 Postcount: 472 |

|

Thank you Sue. |

|

|

Return to top of page · Post #: 26 · Written at 11:51:34 PM on 9 February 2018.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5687 |

|

Interesting? Once again I have had to change to IE as Firefox would not login. Sometimes it messes up the virus program & is a stable as a bucket of weeping gelignite. |

|

|

Return to top of page · Post #: 27 · Written at 10:42:37 AM on 14 February 2018.

|

|

|

|

Location: Adelaide, SA

Member since 27 February 2010 Member #: 630 Postcount: 398 |

|

Hi Sue ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ Valve radios, They just don't make them like they used to |

|

|

Return to top of page · Post #: 28 · Written at 8:00:50 PM on 17 February 2018.

|

|

|

|

Location: Daylesford, VIC

Member since 13 January 2011 Member #: 809 Postcount: 326 |

|

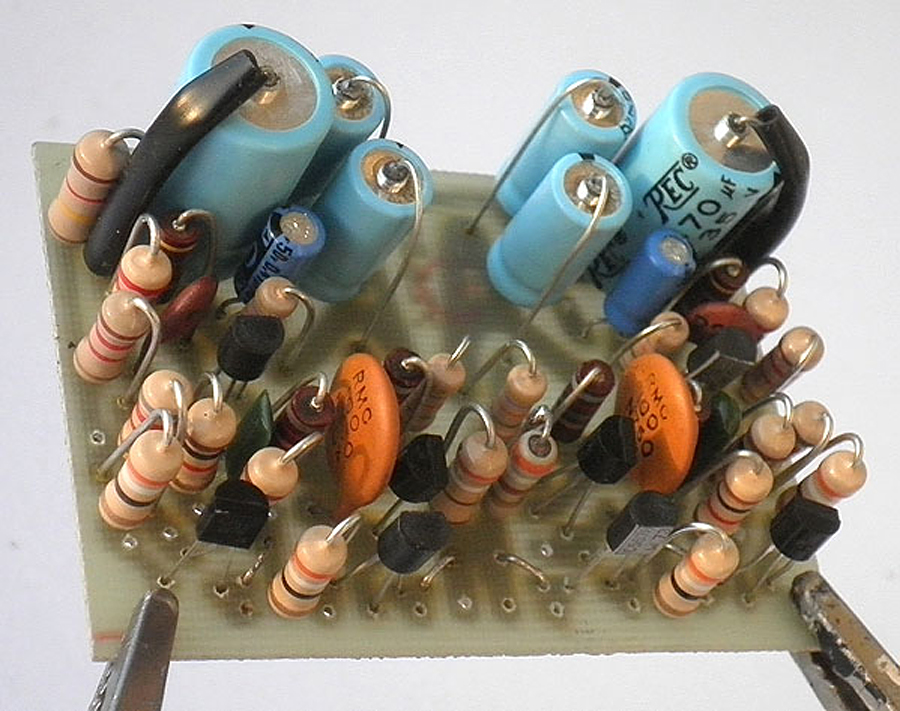

I've taken a chance and made a board now. It wasn't as difficult as I thought. Only one drill broken! Being hand drawn it looked a bit rough coming out of the etch bath, but now it's tinned and soldered it looks very neat. Assuming it works, the problem's solved.  |

|

|

Return to top of page · Post #: 29 · Written at 8:30:52 PM on 17 February 2018.

|

|

|

|

Location: Toongabbie, NSW

Member since 19 November 2015 Member #: 1828 Postcount: 1400 |

|

Hi Sue, you beauty!!!!!! |

|

|

Return to top of page · Post #: 30 · Written at 12:15:33 AM on 18 February 2018.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5687 |

|

Saw the ultimate answer in Diyode Mag. Its a desktop milling machine that can engrave. That means it can cut out PC patterns & examples are shown. |

|

|

You need to be a member to post comments on this forum.

|

|

Sign In

Vintage Radio and Television is proudly brought to you by an era where things were built with pride and made to last.

DISCLAIMER: Valve radios and televisions contain voltages that can deliver lethal shocks. You should not attempt to work on a valve radio or other electrical appliances unless you know exactly what you are doing and have gained some experience with electronics and working around high voltages. The owner, administrators and staff of Vintage Radio & Television will accept no liability for any damage, injury or loss of life that comes as a result of your use or mis-use of information on this website. Please read our Safety Warning before using this website.

WARNING: Under no circumstances should you ever apply power to a vintage radio, television or other electrical appliance you have acquired without first having it checked and serviced by an experienced person. Also, at no time should any appliance be connected to an electricity supply if the power cord is damaged. If in doubt, do not apply power.

Shintara - Keepin' It Real · VileSilencer - Maintain The Rage