Tech Talk

Forum home - Go back to Tech talk

|

Potentiometer shaft extension

|

|

|

« Back ·

1 ·

Next »

|

|

|

Return to top of page · Post #: 1 · Written at 9:14:40 PM on 11 August 2013.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

It looks like I'm going to be replacing a potentiometer with a long shaft (6cm), and I can't find a new one. Seems more practical to extend the shaft on a readily-available one with a shorter shaft. |

|

|

Return to top of page · Post #: 2 · Written at 10:06:49 PM on 11 August 2013.

|

|

|

|

Location: Maclean, NSW

Member since 30 May 2008 Member #: 291 Postcount: 341 |

|

I machine my own from brass rod, I guess you need a lathe which probably not many radio people have. I have two lathes and a mill. |

|

|

Return to top of page · Post #: 3 · Written at 10:52:16 PM on 11 August 2013.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6908 |

|

Shaft extenders are available in the USA, such as here: |

|

|

Return to top of page · Post #: 4 · Written at 8:30:07 AM on 12 August 2013.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

Hmm - that DIY job looks like it also adapts to a different shaft diameter, but it might result in a wobbly knob where the knob, as in my case, is just suspended at the end of the shaft, no second bush. |

|

|

Return to top of page · Post #: 5 · Written at 9:32:03 AM on 12 August 2013.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5663 |

|

Does not really matter what is used sometimes. I have made them from Brass, Aluminium & Nylon. |

|

|

Return to top of page · Post #: 6 · Written at 7:24:44 PM on 13 August 2013.

|

|

|

|

Location: Maclean, NSW

Member since 30 May 2008 Member #: 291 Postcount: 341 |

|

There are shaft extension kits here on eBay: |

|

|

Return to top of page · Post #: 7 · Written at 8:06:58 PM on 13 August 2013.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6908 |

|

Jaycar part number CAT. NO. YG2790 |

|

|

Return to top of page · Post #: 8 · Written at 9:18:06 PM on 13 August 2013.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

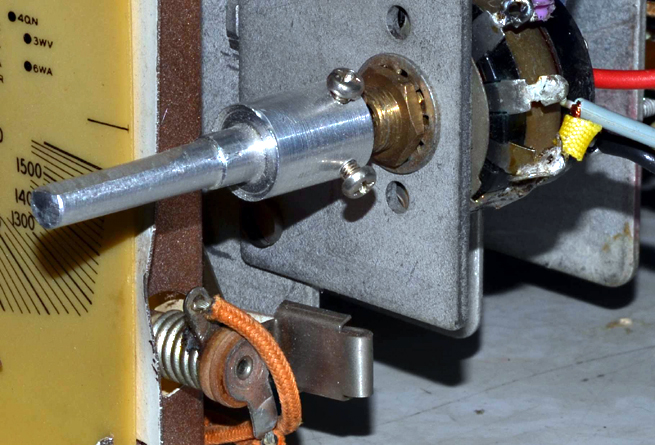

After trying a couple of DIY coupling tecniques, I gave up and bought a Jaycar "shaft coupler" for $6.95. |

|

|

Return to top of page · Post #: 9 · Written at 7:08:44 PM on 14 August 2013.

|

|

|

|

Location: Maclean, NSW

Member since 30 May 2008 Member #: 291 Postcount: 341 |

|

OK on trying to make one for $6.95. |

|

|

Return to top of page · Post #: 10 · Written at 8:02:15 PM on 14 August 2013.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6908 |

|

Yes, you'd be hard-pressed to make one for $6.95 if you were charging for your time. |

|

|

Return to top of page · Post #: 11 · Written at 8:44:05 PM on 14 August 2013.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5663 |

|

I do not consider filing down the pot shaft good. That is not without risk to the pot. Even that it is done outside of the radio. |

|

|

Return to top of page · Post #: 12 · Written at 5:59:06 PM on 20 October 2013.

|

|

|

|

Location: Wellington, NZ

Member since 24 July 2009 Member #: 517 Postcount: 63 |

|

Slip heatshrink onto the longer of the shafts, align the shafts, run a small amount of supaglue over the surfaces, slide the heatshrink over the join. When the glue has dried, apply heat. This is cheap, only a bit nasty & works well. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ 6A8G. |

|

|

Return to top of page · Post #: 13 · Written at 6:24:24 PM on 20 October 2013.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

Heatshrink tecnique sounds good - if you are confident you can get a good straight alignment before gluing. How do you align a flattened end to a round end? |

|

|

Return to top of page · Post #: 14 · Written at 7:37:42 PM on 20 October 2013.

|

|

|

|

Location: Wellington, NZ

Member since 24 July 2009 Member #: 517 Postcount: 63 |

|

Whoops! Forgot to mention, make a hacksaw cut ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ 6A8G. |

|

|

Return to top of page · Post #: 15 · Written at 9:37:00 PM on 20 October 2013.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5663 |

|

I can see why I have no stress with extension shafts. Rarely does one find the right length.  If the knob is a bit dodgy and the hole is oversize shrink tube works, if you need to make an extension shaft, for the set with it you have the option of turning it oversize. You can sometimes recycle the shaft of a dead pot & use a socket. I will make the extension shaft a one piece job and I have made them to fit those spline shaft pots. Often its hang the cost & time. If you know you are not going to find the thing, the time that would be wasted looking: is better spent making. Do check RS components & way the costs, they have some long shaft pots. Marc |

|

|

« Back ·

1 ·

Next »

|

|

|

You need to be a member to post comments on this forum.

|

|

Sign In

Vintage Radio and Television is proudly brought to you by an era where things were built with pride and made to last.

DISCLAIMER: Valve radios and televisions contain voltages that can deliver lethal shocks. You should not attempt to work on a valve radio or other electrical appliances unless you know exactly what you are doing and have gained some experience with electronics and working around high voltages. The owner, administrators and staff of Vintage Radio & Television will accept no liability for any damage, injury or loss of life that comes as a result of your use or mis-use of information on this website. Please read our Safety Warning before using this website.

WARNING: Under no circumstances should you ever apply power to a vintage radio, television or other electrical appliance you have acquired without first having it checked and serviced by an experienced person. Also, at no time should any appliance be connected to an electricity supply if the power cord is damaged. If in doubt, do not apply power.

Shintara - Keepin' It Real · VileSilencer - Maintain The Rage

90 degrees to the flattened bit. Then file a tongue into the extension. I cheated, took it to work & did this bit on the bench grinder. Then glue/heatshrink. If you ever need to dissassemble, I reckon a bend in line with the tongue zas opposed to across it would work. As I said, no particularly elegant but it does work

90 degrees to the flattened bit. Then file a tongue into the extension. I cheated, took it to work & did this bit on the bench grinder. Then glue/heatshrink. If you ever need to dissassemble, I reckon a bend in line with the tongue zas opposed to across it would work. As I said, no particularly elegant but it does work