Tech Talk

Forum home - Go back to Tech talk

|

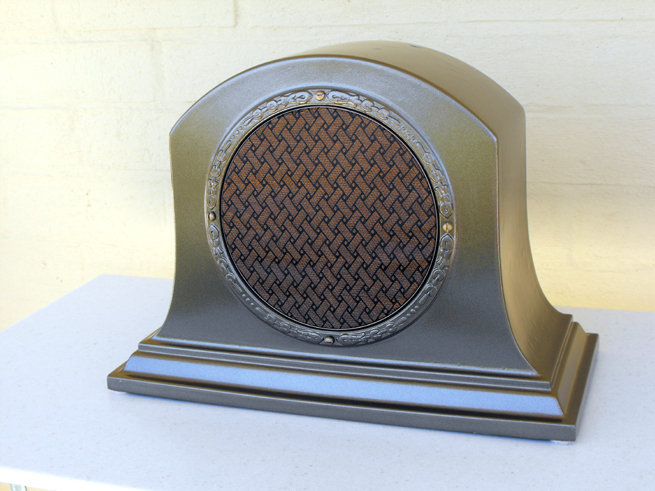

RCA 100A Speaker base

|

|

|

« Back ·

1 ·

Next »

|

|

|

Return to top of page · Post #: 1 · Written at 5:25:34 PM on 4 October 2012.

|

|

|

|

Location: Cameron Park, NSW

Member since 5 November 2010 Member #: 770 Postcount: 425 |

|

Help wanted. |

|

|

Return to top of page · Post #: 2 · Written at 7:31:24 PM on 4 October 2012.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7548 |

|

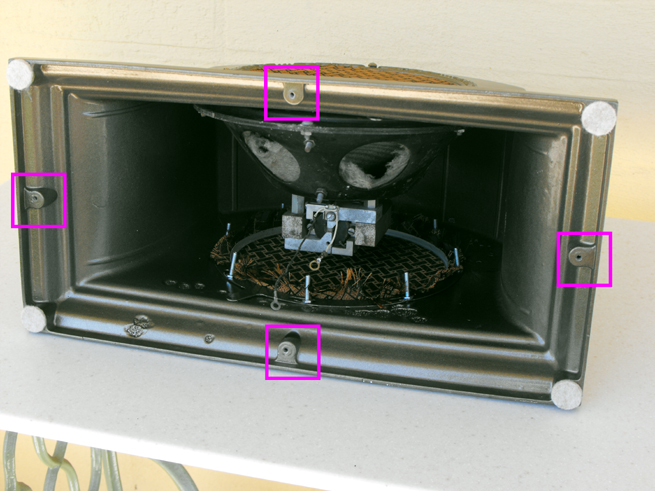

It'd be best if you sent me a photo of where the screws go on the speaker for publication. There were several types of imperial threads, Whitworth, UNC, UNF, etc. Being American it's more likely to be one of the latter two though it also depends on whether the screws are self-tapping or have machine threads. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 3 · Written at 11:35:00 AM on 5 October 2012.

|

|

|

|

Location: Cameron Park, NSW

Member since 5 November 2010 Member #: 770 Postcount: 425 |

|

Just clarifying, the screws are machine thread, not self tappers and photos are on their way. They would be about 1/2 inch in the old scale.   Thanks folks Harold |

|

|

Return to top of page · Post #: 4 · Written at 12:12:51 AM on 6 October 2012.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7548 |

|

Probably 1/2 long but the gauge would be closer to 1/8 or 3/16. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 5 · Written at 10:46:54 AM on 6 October 2012.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5595 |

|

Based on my repairs of American equipment that is likely to not have 1/8" or 3/16" |

|

|

Return to top of page · Post #: 6 · Written at 5:30:05 PM on 8 October 2012.

|

|

|

|

Location: Cameron Park, NSW

Member since 5 November 2010 Member #: 770 Postcount: 425 |

|

Thanks to all for your suggestions, I am sure they are UNF as Google tells me that they have been in use for ever. |

|

|

« Back ·

1 ·

Next »

|

|

|

You need to be a member to post comments on this forum.

|

|

Sign In

Vintage Radio and Television is proudly brought to you by an era where things were built with pride and made to last.

DISCLAIMER: Valve radios and televisions contain voltages that can deliver lethal shocks. You should not attempt to work on a valve radio or other electrical appliances unless you know exactly what you are doing and have gained some experience with electronics and working around high voltages. The owner, administrators and staff of Vintage Radio & Television will accept no liability for any damage, injury or loss of life that comes as a result of your use or mis-use of information on this website. Please read our Safety Warning before using this website.

WARNING: Under no circumstances should you ever apply power to a vintage radio, television or other electrical appliance you have acquired without first having it checked and serviced by an experienced person. Also, at no time should any appliance be connected to an electricity supply if the power cord is damaged. If in doubt, do not apply power.

Shintara - Keepin' It Real · VileSilencer - Maintain The Rage