Tech Talk

Forum home - Go back to Tech talk

|

Purpose of felt annulus in speaker

|

|

|

Return to top of page · Post #: 1 · Written at 8:59:26 PM on 14 July 2025.

|

|

|

|

Location: NSW

Member since 10 June 2010 Member #: 681 Postcount: 1379 |

|

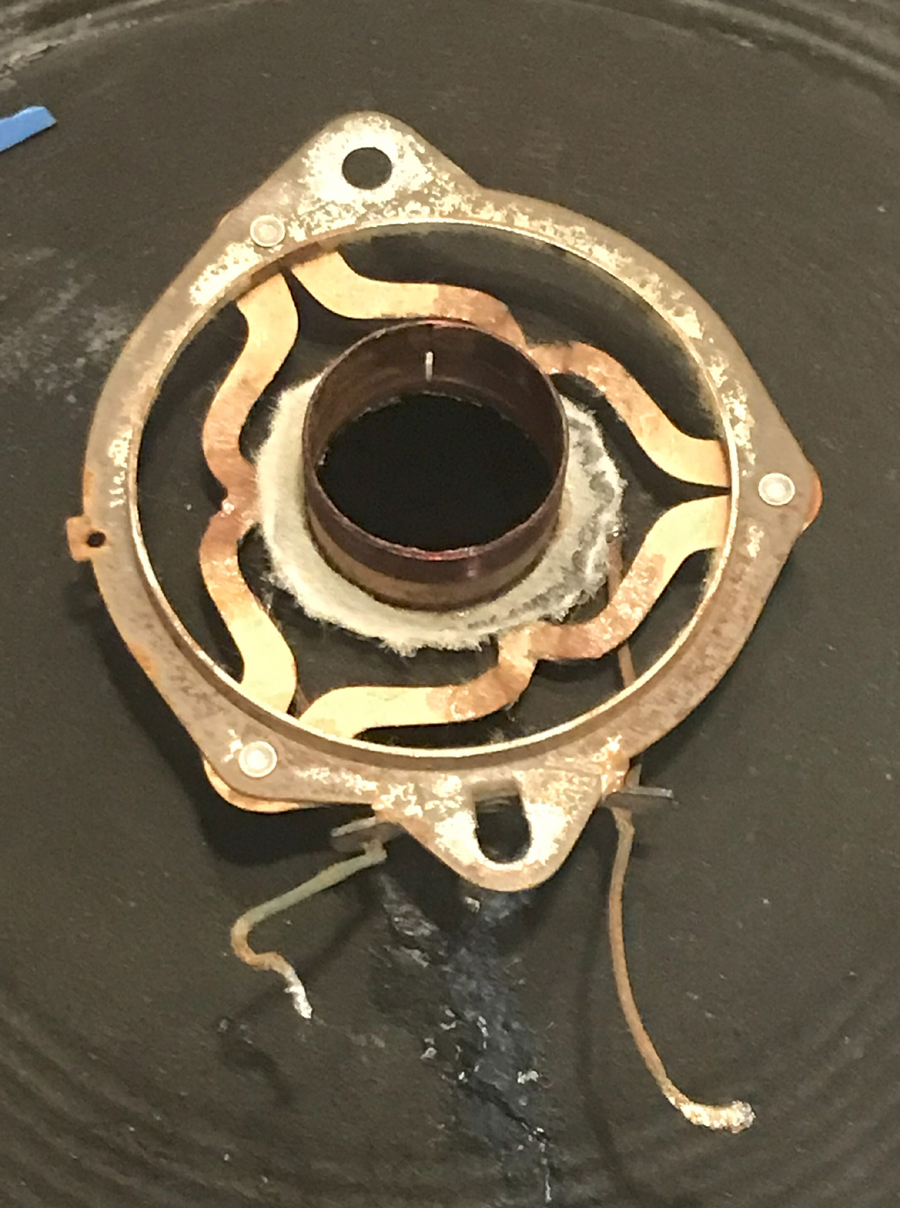

I have been restoring a speaker and discovered a felt annulus between the magnet plate of the electromagnet and the bottom of the speaker basket, under the voice coil centreing spider support. I've sent in a photo with its remnants in place. |

|

|

Return to top of page · Post #: 2 · Written at 4:28:40 PM on 15 July 2025.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5607 |

|

Air will still be vented even if the dust cover is solid, or porous. The speaker will sound horrid if its poling, where the voice coil tube rubs on the edges of the magnet. Normal cause is "off" centre due to the spider being damaged. |

|

|

Return to top of page · Post #: 3 · Written at 5:12:40 PM on 15 July 2025.

|

|

|

|

Location: NSW

Member since 10 June 2010 Member #: 681 Postcount: 1379 |

|

My intention is to fix the new corrugated spider to its support and the voice coil, then connect the speaker to the radio and apply just enough volume to make sure everything is nicely centred. And then fit the cone. Hopefully this will avoid poling.       |

|

|

Return to top of page · Post #: 4 · Written at 7:03:22 PM on 15 July 2025.

|

|

|

|

Location: Belrose, NSW

Member since 31 December 2015 Member #: 1844 Postcount: 2643 |

|

I have found PVA woodworking glue to be the best glue to use on speaker cones and related parts. |

|

|

Return to top of page · Post #: 5 · Written at 7:33:09 PM on 15 July 2025.

|

|

|

|

Location: Nuriootpa, SA

Member since 28 June 2025 Member #: 2734 Postcount: 40 |

|

I saw online someone use silicone for broken speaker cones |

|

|

Return to top of page · Post #: 6 · Written at 7:39:42 PM on 15 July 2025.

|

|

|

|

Location: Belrose, NSW

Member since 31 December 2015 Member #: 1844 Postcount: 2643 |

|

Actually PVA is a better match in terms of flexibility and it's much easier to work with. And it dries clear. |

|

|

Return to top of page · Post #: 7 · Written at 7:55:58 PM on 15 July 2025.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5607 |

|

I was up until recently using Acrylic based QuickGrip often in conjunction with medical Micropore (non woven) for many tears & holes. However, it appears that it has disappeared. The Acrylic never really dries rigid (and I have made several tons of it). |

|

|

Return to top of page · Post #: 8 · Written at 8:00:51 PM on 15 July 2025.

|

|

|

|

Location: NSW

Member since 10 June 2010 Member #: 681 Postcount: 1379 |

|

I already have some PVA craft glue which is acid free and claims to be repositionable which should suit for getting things nicely lined up. |

|

|

Return to top of page · Post #: 9 · Written at 11:25:41 PM on 16 July 2025.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5607 |

|

Sealing the inside of the cone may restrict airflow but not stop it. The cone will actually be akin to a bellows. As the cone descends air will be be expelled via the outside of the voice coil and drawn back in as the cone is repelled, via the outside of the voice coil, which is not sealed. |

|

|

Return to top of page · Post #: 10 · Written at 5:05:50 AM on 17 July 2025.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7564 |

|

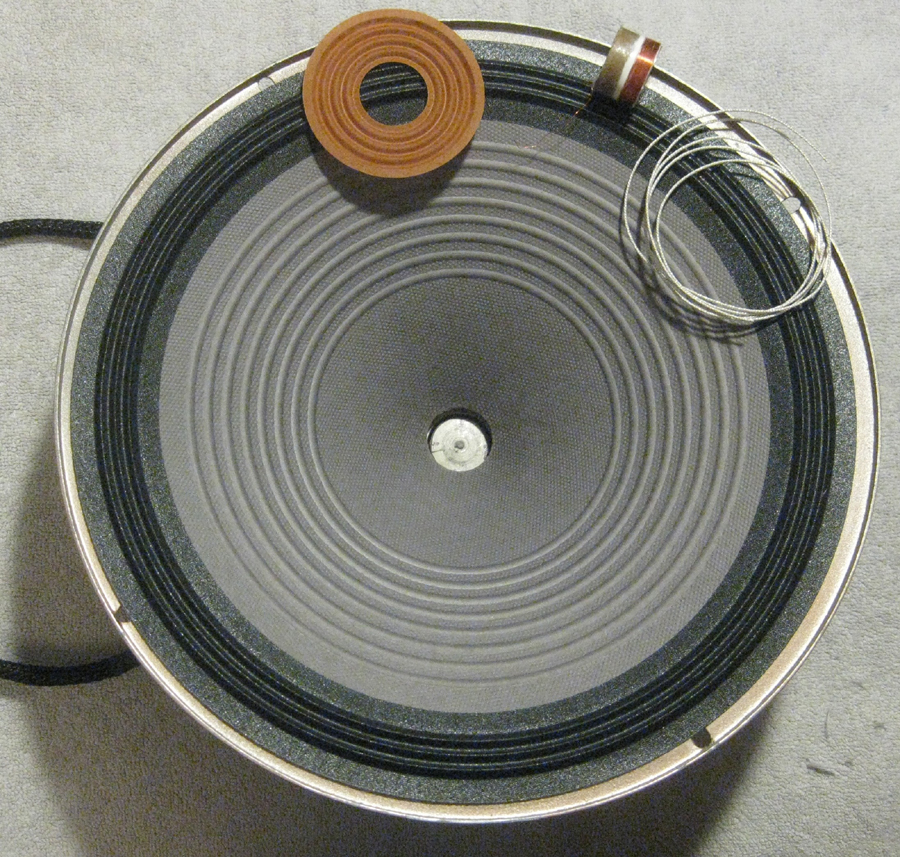

Photos uploaded to Post 3. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 11 · Written at 8:13:18 AM on 17 July 2025.

|

|

|

|

Location: NSW

Member since 10 June 2010 Member #: 681 Postcount: 1379 |

|

I had thought that cooling of the voice coil would be by convection into the magnet pole and plate and not to the outside atmosphere. But something to bear in mind. Good airflow cannot hurt as far as cooling is concerned. |

|

|

Return to top of page · Post #: 12 · Written at 5:28:00 PM on 17 July 2025.

|

|

|

|

Location: NSW

Member since 10 June 2010 Member #: 681 Postcount: 1379 |

|

Have added explanations of the photos to Post #3. |

|

|

Return to top of page · Post #: 13 · Written at 10:00:20 PM on 17 July 2025.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7564 |

|

When doing repairs, I use PVA on the cone and silicone sealant on the flexible suspension bits. If the whole suspension has disintegrated, I've been known to replace only the outer half of the cone so as to not disturb the voice coil any more than needed. I have some scraps of old film (blank negatives) to use to 'centre' the voice coil if it has been poling on the magnet. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 14 · Written at 8:27:10 AM on 18 July 2025.

|

|

|

|

Location: NSW

Member since 10 June 2010 Member #: 681 Postcount: 1379 |

|

When restoring the cone this time I decided to spray the cone with paint to deter something chewing on it, presumably silverfish. Even though I tried to so this evenly, the cone when dried had a rattle I could not eliminate. I think the painting caused distortion which pulled the voicecoil out of line. I tried to recover the voice coil but it didn't survive being removed from the cone. So a total rebuild resulted, as the spider couldn't be repaired as I had done in 1989. |

|

|

Return to top of page · Post #: 15 · Written at 9:32:53 AM on 18 July 2025.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5607 |

|

I do not like any glue that sets rigid, that is likely to cause tearing if used on the convoluted rim. For some unknown reason Acrylic "Quick Grip" has disappeared. It remained flexible and tacky, so needed talc on it if exposed. |

|

|

You need to be a member to post comments on this forum.

|

|

Sign In

Vintage Radio and Television is proudly brought to you by an era where things were built with pride and made to last.

DISCLAIMER: Valve radios and televisions contain voltages that can deliver lethal shocks. You should not attempt to work on a valve radio or other electrical appliances unless you know exactly what you are doing and have gained some experience with electronics and working around high voltages. The owner, administrators and staff of Vintage Radio & Television will accept no liability for any damage, injury or loss of life that comes as a result of your use or mis-use of information on this website. Please read our Safety Warning before using this website.

WARNING: Under no circumstances should you ever apply power to a vintage radio, television or other electrical appliance you have acquired without first having it checked and serviced by an experienced person. Also, at no time should any appliance be connected to an electricity supply if the power cord is damaged. If in doubt, do not apply power.

Shintara - Keepin' It Real · VileSilencer - Maintain The Rage