Tech Talk

Forum home - Go back to Tech talk

|

Tuner belt

|

|

|

Return to top of page · Post #: 1 · Written at 6:38:40 PM on 17 August 2024.

|

|

|

|

Location: Two Wells, SA

Member since 16 August 2024 Member #: 2672 Postcount: 33 |

|

I think my radio needs a tuning belt, it had a string which was not in alignment and kept jamming the wheel.    |

|

|

Return to top of page · Post #: 2 · Written at 7:05:33 PM on 17 August 2024.

|

|

|

|

Location: Hill Top, NSW

Member since 18 September 2015 Member #: 1801 Postcount: 2225 |

|

|

|

|

Return to top of page · Post #: 3 · Written at 7:29:19 PM on 17 August 2024.

|

|

|

|

Location: Belrose, NSW

Member since 31 December 2015 Member #: 1844 Postcount: 2652 |

|

WES components stock belt kits for VCRs. If you can't find something there that'll fit you aren't trying!! |

|

|

Return to top of page · Post #: 4 · Written at 10:40:39 PM on 17 August 2024.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6897 |

|

I've never heard of a tuning belt. |

|

|

Return to top of page · Post #: 5 · Written at 7:41:53 AM on 18 August 2024.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7571 |

|

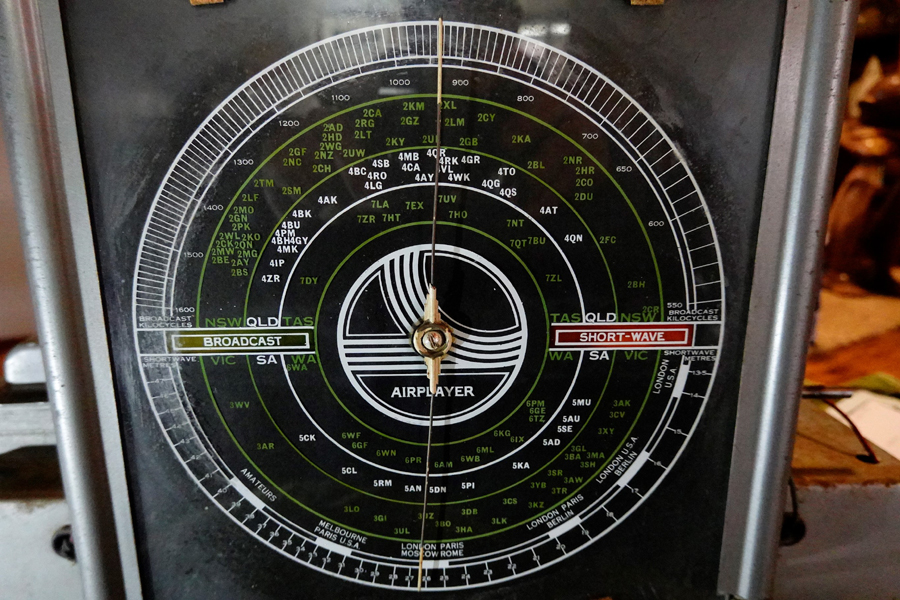

Photos uploaded. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 6 · Written at 8:17:35 AM on 18 August 2024.

|

|

|

|

Location: Hill Top, NSW

Member since 18 September 2015 Member #: 1801 Postcount: 2225 |

|

Thanks for the photos. Well it's definitely not a friction drive, and that string is horrible. Maybe a normal real dial cord might work? |

|

|

Return to top of page · Post #: 7 · Written at 8:58:14 AM on 18 August 2024.

|

|

|

|

Location: NSW

Member since 10 June 2010 Member #: 681 Postcount: 1379 |

|

Looks like the jam-jar lid is glued to the flywheel of the tuning shaft. The flywheel appears to be diecast zinc, and even though it does't look like it in the photograph, this may have started to crack up as diecast zinc eventually does, due to impurities in the zinc and corrosion. Maybe the lid is there to to hold the flywheel together. |

|

|

Return to top of page · Post #: 8 · Written at 9:13:54 AM on 18 August 2024.

|

|

|

|

Location: Belrose, NSW

Member since 31 December 2015 Member #: 1844 Postcount: 2652 |

|

And that tuning mech looks like it could be a friction drive - NO! now that I've seen the pictures! |

|

|

Return to top of page · Post #: 9 · Written at 1:13:10 PM on 18 August 2024.

|

|

|

|

Location: Hill Top, NSW

Member since 18 September 2015 Member #: 1801 Postcount: 2225 |

|

There's a spring in the photo, just dangling there, on the end of the string, which looks like a bootlace. The eyelet is there too, for the other end of the cord. |

|

|

Return to top of page · Post #: 10 · Written at 1:20:23 PM on 18 August 2024.

|

|

|

|

Location: Two Wells, SA

Member since 16 August 2024 Member #: 2672 Postcount: 33 |

|

Thanks for replies, once I unglued the jam jar lid the pulley seemed in good condition. |

|

|

Return to top of page · Post #: 11 · Written at 7:48:56 PM on 18 August 2024.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7571 |

|

Starting a new thread is fine if, as in this case, a specific topic on one aspect of restoration is being discussed. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 12 · Written at 8:23:40 PM on 18 August 2024.

|

|

|

|

Location: Toongabbie, NSW

Member since 19 November 2015 Member #: 1828 Postcount: 1385 |

|

Looks like an attempt to change the ratio of the drive and speed up the dial movement. |

|

|

Return to top of page · Post #: 13 · Written at 10:07:46 PM on 18 August 2024.

|

|

|

|

Location: Two Wells, SA

Member since 16 August 2024 Member #: 2672 Postcount: 33 |

|

Fred, is it common for the string to go around the spindle shaft which is a small diameter, because it looks like the lower pulley is supposed to be there. |

|

|

Return to top of page · Post #: 14 · Written at 10:18:23 PM on 18 August 2024.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5632 |

|

That looks like a standard drum especially as it has an inertia wheel. Based on experience, some had absolutely no idea of mechanical interpretation & I have seen some wonderous things. |

|

|

Return to top of page · Post #: 15 · Written at 7:03:12 AM on 19 August 2024.

|

|

|

|

Location: Toongabbie, NSW

Member since 19 November 2015 Member #: 1828 Postcount: 1385 |

|

Hi Johnny. |

|

|

You need to be a member to post comments on this forum.

|

|

Sign In

Vintage Radio and Television is proudly brought to you by an era where things were built with pride and made to last.

DISCLAIMER: Valve radios and televisions contain voltages that can deliver lethal shocks. You should not attempt to work on a valve radio or other electrical appliances unless you know exactly what you are doing and have gained some experience with electronics and working around high voltages. The owner, administrators and staff of Vintage Radio & Television will accept no liability for any damage, injury or loss of life that comes as a result of your use or mis-use of information on this website. Please read our Safety Warning before using this website.

WARNING: Under no circumstances should you ever apply power to a vintage radio, television or other electrical appliance you have acquired without first having it checked and serviced by an experienced person. Also, at no time should any appliance be connected to an electricity supply if the power cord is damaged. If in doubt, do not apply power.

Shintara - Keepin' It Real · VileSilencer - Maintain The Rage

#$$ useless..

#$$ useless..