Tech Talk

Forum home - Go back to Tech talk

|

Mullard 98

|

|

|

Return to top of page · Post #: 31 · Written at 10:54:28 AM on 19 March 2023.

|

|

|

|

Location: Linton, VIC

Member since 30 December 2016 Member #: 2028 Postcount: 472 |

|

Gandhn is correct. |

|

|

Return to top of page · Post #: 32 · Written at 8:21:08 PM on 19 March 2023.

|

|

|

|

Location: Toongabbie, NSW

Member since 19 November 2015 Member #: 1828 Postcount: 1379 |

|

Hi Harold, BBTV, yep but modifying is the spice of life! |

|

|

Return to top of page · Post #: 33 · Written at 8:38:29 PM on 19 March 2023.

|

|

|

|

Location: Linton, VIC

Member since 30 December 2016 Member #: 2028 Postcount: 472 |

|

Indeed it is Fred, I must admit I have (and still do) carried out some extraordinary mods during my service life. |

|

|

Return to top of page · Post #: 34 · Written at 9:54:10 AM on 20 March 2023.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5595 |

|

If that is a rubber mounted gang and they have decomposed? That is liable to be most of the clearance problem. |

|

|

Return to top of page · Post #: 35 · Written at 5:31:53 PM on 25 March 2023.

|

|

|

|

Location: Eleebana, NSW

Member since 17 February 2016 Member #: 1876 Postcount: 18 |

|

Hi All, As far as I'm concerned, the dial drive issue is resolved. It may not be strictly in line with genuine restoration work but it works..!! |

|

|

Return to top of page · Post #: 36 · Written at 2:44:50 PM on 8 April 2023.

|

|

|

|

Location: Eleebana, NSW

Member since 17 February 2016 Member #: 1876 Postcount: 18 |

|

Hello everyone.   |

|

|

Return to top of page · Post #: 37 · Written at 2:55:42 PM on 9 April 2023.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7548 |

|

Photos uploaded to Post 36. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 38 · Written at 4:32:47 PM on 9 April 2023.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5595 |

|

It would not be too hard to mount another pulley, or roller under the cordage to force it up. Now I wonder if they used Dulux? |

|

|

Return to top of page · Post #: 39 · Written at 5:15:10 PM on 9 April 2023.

|

|

|

|

Location: NSW

Member since 10 June 2010 Member #: 681 Postcount: 1370 |

|

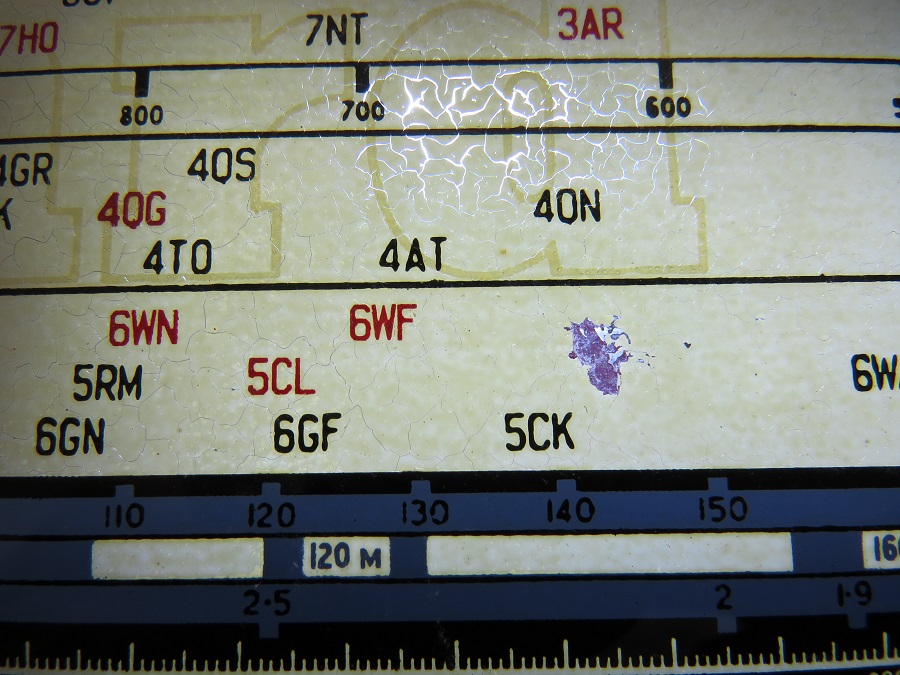

If you can organise edge lighting of the glass so that light is not actually shining through it ie with a shield to prevent light shining through the glass and to direct the light in through the edge of the glass, then the crazing may not be as obvious when sprayed over. |

|

|

Return to top of page · Post #: 40 · Written at 6:33:18 PM on 9 April 2023.

|

|

|

|

Location: Eleebana, NSW

Member since 17 February 2016 Member #: 1876 Postcount: 18 |

|

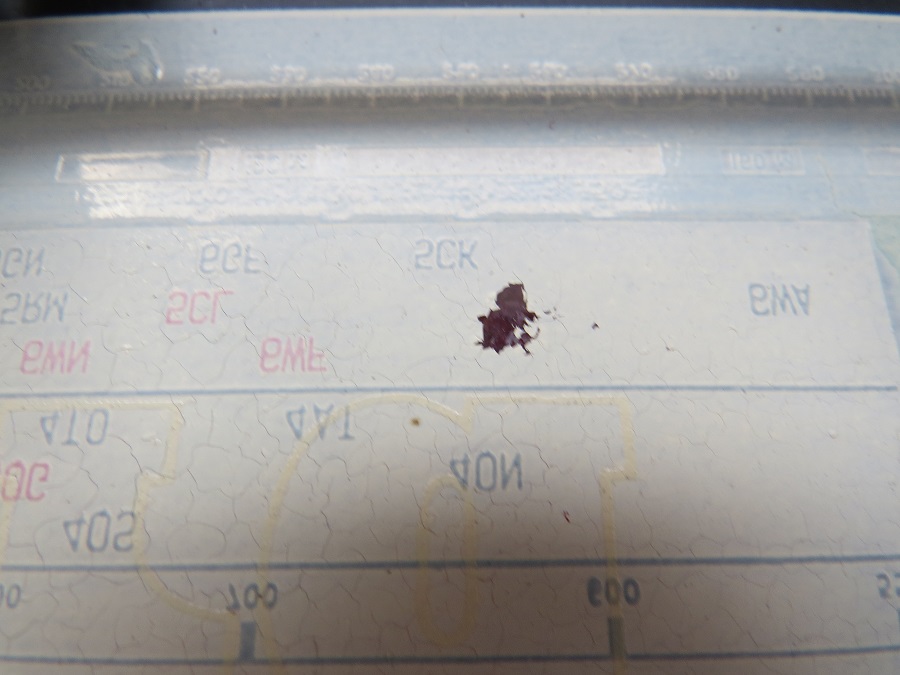

Bits of the paint or ink are falling off even while you look at it. So I have to stabilise it pretty soon. |

|

|

Return to top of page · Post #: 41 · Written at 6:39:03 PM on 9 April 2023.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6882 |

|

|

|

|

Return to top of page · Post #: 42 · Written at 6:43:05 PM on 9 April 2023.

|

|

|

|

Location: NSW

Member since 10 June 2010 Member #: 681 Postcount: 1370 |

|

I have had Michael do a dial for me, a transfer or decal. Michael can work from a colour scan; a scan would be a prudent precaution against disaster anyway. |

|

|

Return to top of page · Post #: 43 · Written at 8:55:37 AM on 10 April 2023.

|

|

|

|

Location: Hobart, TAS

Member since 31 July 2016 Member #: 1959 Postcount: 578 |

|

I have used hairspray with great permanent results. Even 20 years later. |

|

|

You need to be a member to post comments on this forum.

|

|

Sign In

Vintage Radio and Television is proudly brought to you by an era where things were built with pride and made to last.

DISCLAIMER: Valve radios and televisions contain voltages that can deliver lethal shocks. You should not attempt to work on a valve radio or other electrical appliances unless you know exactly what you are doing and have gained some experience with electronics and working around high voltages. The owner, administrators and staff of Vintage Radio & Television will accept no liability for any damage, injury or loss of life that comes as a result of your use or mis-use of information on this website. Please read our Safety Warning before using this website.

WARNING: Under no circumstances should you ever apply power to a vintage radio, television or other electrical appliance you have acquired without first having it checked and serviced by an experienced person. Also, at no time should any appliance be connected to an electricity supply if the power cord is damaged. If in doubt, do not apply power.

Shintara - Keepin' It Real · VileSilencer - Maintain The Rage

Rogermark FYI: Michael Ranaan in Chatswood makes dial reproductions based on what remains of original dials.

Rogermark FYI: Michael Ranaan in Chatswood makes dial reproductions based on what remains of original dials.