Tech Talk

Forum home - Go back to Tech talk

|

Mullard 98

|

|

|

Return to top of page · Post #: 16 · Written at 2:09:32 PM on 20 February 2023.

|

|

|

|

Location: Hill Top, NSW

Member since 18 September 2015 Member #: 1801 Postcount: 2177 |

|

Looking at the photo from the manual, the cord is connected correctly, and the counter-intuitive action of the pointer is correct. |

|

|

Return to top of page · Post #: 17 · Written at 7:20:19 PM on 20 February 2023.

|

|

|

|

Location: Linton, VIC

Member since 30 December 2016 Member #: 2028 Postcount: 472 |

|

Robbbert makes a good point------I have a '54 Philips made in the UK with the same arse-about dial set up. |

|

|

Return to top of page · Post #: 18 · Written at 7:40:04 PM on 20 February 2023.

|

|

|

|

Location: NSW

Member since 10 June 2010 Member #: 681 Postcount: 1350 |

|

If you hit the knob at the bottom with your fingers to tune, then the present arrangement makes sense. |

|

|

Return to top of page · Post #: 19 · Written at 7:44:33 PM on 20 February 2023.

|

|

|

|

Location: Linton, VIC

Member since 30 December 2016 Member #: 2028 Postcount: 472 |

|

If I can add to my last comment--------. |

|

|

Return to top of page · Post #: 20 · Written at 8:44:38 PM on 20 February 2023.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5554 |

|

I find it difficult to imagine that Philips would design, or release, a set which when correctly strung, would drag, or rub the cordage on the bracket, unless its strung with the wrong stuff.. |

|

|

Return to top of page · Post #: 21 · Written at 10:02:40 PM on 20 February 2023.

|

|

|

|

Location: Hill Top, NSW

Member since 18 September 2015 Member #: 1801 Postcount: 2177 |

|

It will only rub the bracket if it was hacked. Stringing the correct way will avoid that. |

|

|

Return to top of page · Post #: 22 · Written at 1:15:11 AM on 21 February 2023.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5554 |

|

Precisely, if done correctly, lots of things work correctly. Unfortunately I have seen lots of things arrive here that have been monkeyed with, making things just that little bit more interesting & often too expensive or damaged to repair. |

|

|

Return to top of page · Post #: 23 · Written at 7:47:03 AM on 21 February 2023.

|

|

|

|

Location: Linton, VIC

Member since 30 December 2016 Member #: 2028 Postcount: 472 |

|

Good point about the wooden pulleys, my UK Philips employs them |

|

|

Return to top of page · Post #: 24 · Written at 10:02:47 AM on 21 February 2023.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5554 |

|

The very early radios were like that where they tracked by wavelength and not frequency. When the rotor vanes are fully open that is the highest frequency and shortest wavelength. The European sets tended to stay with metre bands. |

|

|

Return to top of page · Post #: 25 · Written at 4:00:15 PM on 17 March 2023.

|

|

|

|

Location: Eleebana, NSW

Member since 17 February 2016 Member #: 1876 Postcount: 18 |

|

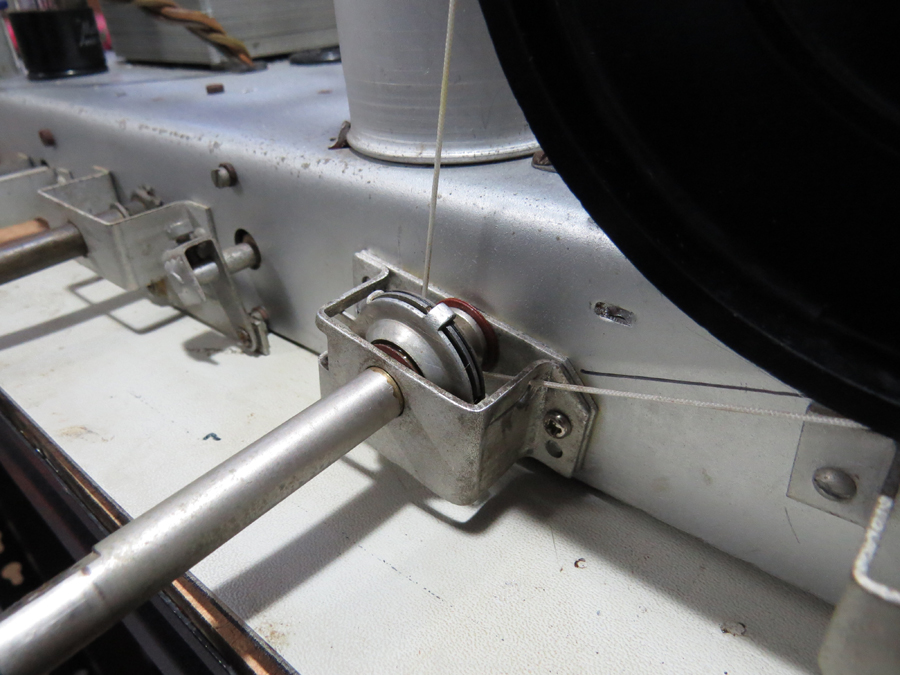

Hi All, I fixed the dial movement issue by drilling a hole in the bracket of the drive spindle such that the cord is no longer crossed over.    |

|

|

Return to top of page · Post #: 26 · Written at 1:53:29 PM on 18 March 2023.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7518 |

|

Photos uploaded to Post 25. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 27 · Written at 2:57:35 PM on 18 March 2023.

|

|

|

|

Location: Cameron Park, NSW

Member since 5 November 2010 Member #: 770 Postcount: 425 |

|

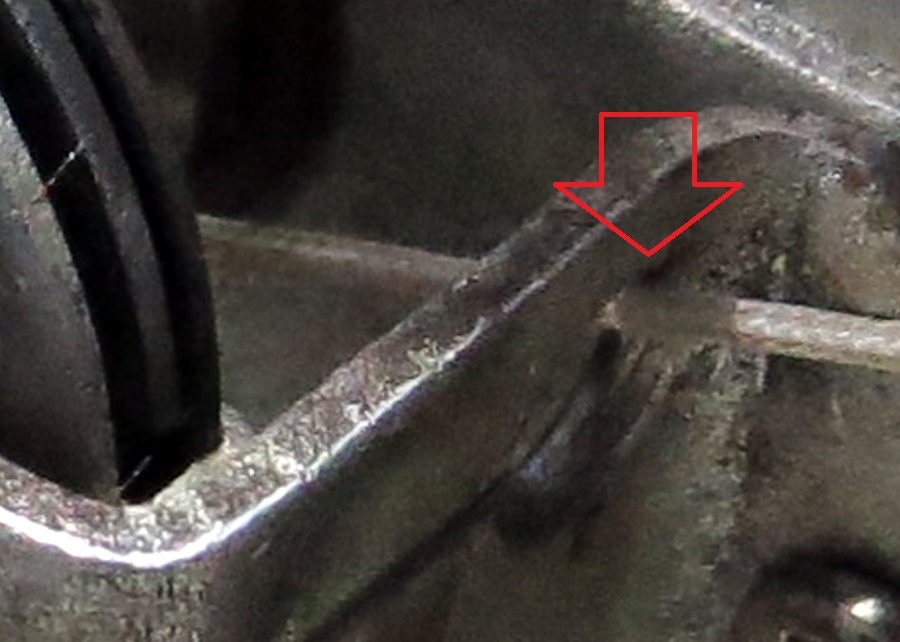

The bracket holding the tuning knob shaft appears to have an alternative mounting position, slightly rotated.  |

|

|

Return to top of page · Post #: 28 · Written at 8:09:21 PM on 18 March 2023.

|

|

|

|

Location: Toongabbie, NSW

Member since 19 November 2015 Member #: 1828 Postcount: 1366 |

|

Dim bulb start up installation = TICK.! |

|

|

Return to top of page · Post #: 29 · Written at 8:34:22 PM on 18 March 2023.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7518 |

|

Photo uploaded to Post 27. I think what Harold means is that if you straighten the mounting bracket for the tuning dial, the string will not rub where indicated with the red arrow. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 30 · Written at 9:40:09 AM on 19 March 2023.

|

|

|

|

Location: Cameron Park, NSW

Member since 5 November 2010 Member #: 770 Postcount: 425 |

|

Brad, yes that is it exactly. |

|

|

You need to be a member to post comments on this forum.

|

|

Sign In

Vintage Radio and Television is proudly brought to you by an era where things were built with pride and made to last.

DISCLAIMER: Valve radios and televisions contain voltages that can deliver lethal shocks. You should not attempt to work on a valve radio or other electrical appliances unless you know exactly what you are doing and have gained some experience with electronics and working around high voltages. The owner, administrators and staff of Vintage Radio & Television will accept no liability for any damage, injury or loss of life that comes as a result of your use or mis-use of information on this website. Please read our Safety Warning before using this website.

WARNING: Under no circumstances should you ever apply power to a vintage radio, television or other electrical appliance you have acquired without first having it checked and serviced by an experienced person. Also, at no time should any appliance be connected to an electricity supply if the power cord is damaged. If in doubt, do not apply power.

Shintara - Keepin' It Real · VileSilencer - Maintain The Rage