Workshops, Tools and Test Equipment

Forum home - Go back to Workshops, Tools and Test Equipment

|

Wiring: type choices and routing principles

|

|

|

« Back ·

1 ·

Next »

|

|

|

Return to top of page · Post #: 1 · Written at 2:01:57 PM on 14 September 2012.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

Looks like I may be replacing some valve sockets, so I wondering about best kind of wire for different uses. |

|

|

Return to top of page · Post #: 2 · Written at 11:01:18 PM on 14 September 2012.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7606 |

|

When I look at a typical radio chassis from the 1940's there seems to be a bit of everything. VIR-insulated stranded wire seems to have been used a lot for valve heater wiring and hook-up wire for various top-mounted components like transformers and coils. In later years the insulation was more often PVC or fibreglass though back in the 1930s a product called busbar wire was used. This was a thin-gauge square-section wire either soldered at various points to the chassis or mounted on insulators, as needed. Busbar wire was also used on fibre breadboards in the 1920s. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 3 · Written at 8:45:32 PM on 9 July 2013.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

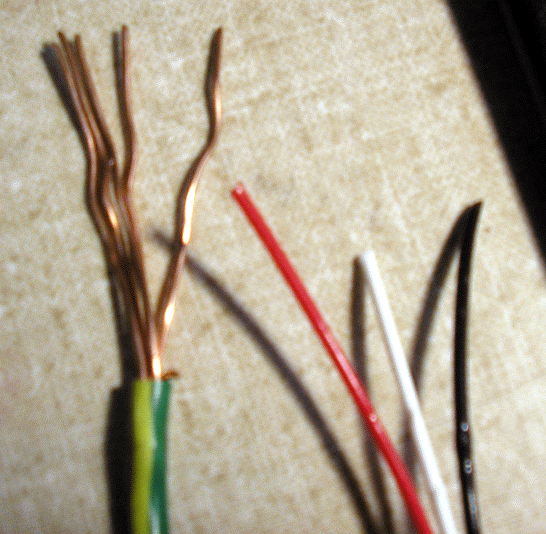

Coming back to this thread because I think I made the wrong choice when replacing some perished original wiring a couple of years back. I used mains-rated multi-strand plastic-insulated copper for all the HT DC connections. Because it conducts heat so well, I had to pour an awful lot of heat onto the valve socket and IF transformer tags to solder the connections. I'm thinking this might have contributed to weakening some connections inside the IF transformers. |

|

|

Return to top of page · Post #: 4 · Written at 9:20:47 PM on 9 July 2013.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6929 |

|

I'm wondering if I could go the opposite direction and use some single-strand copper hook-up wire of the type used in telephone wiring systems. I know it carries 80v in the phone system, and hope it might be robust enough for the small currents in the B+ and audio connections. |

|

|

Return to top of page · Post #: 5 · Written at 10:09:12 PM on 9 July 2013.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

Thanks for the warning - I'll look for a lightish gauge single-strand with solid insulation. Or maybe settle for bare copper with spaghetti tubing. |

|

|

Return to top of page · Post #: 6 · Written at 11:22:17 PM on 9 July 2013.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6929 |

|

I generally use the plastic insulated 300 volt multi-stranded stuff from Altronics and I have some modern cloth covered stuff that I have used on occasion for authenticity when plastic would look out of place. |

|

|

Return to top of page · Post #: 7 · Written at 6:26:27 AM on 10 July 2013.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7606 |

|

If you only need a few scraps of wire you could grab some from old fluorescent lamp fittings. It is something like 0.5mm2 and has V105 insulation so if there is a meltdown inside the radio at a later date the insulation will hang on for longer. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 8 · Written at 12:53:15 PM on 11 July 2013.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

I've noticed a big difference in the time it takes to bring solder to melting point on the IFT lugs if I am using the heavy multi-strand copper. Like about six seconds, compared to 1-2 seconds if I'm attaching a finer wire. I reckon that 6 seconds gives too much time for the other end of that lug INSIDE THE CAN to get to, or close to, fuse temperature. |

|

|

Return to top of page · Post #: 9 · Written at 4:48:25 PM on 11 July 2013.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6929 |

|

I've noticed a big difference in the time it takes to bring solder to melting point on the IFT lugs if I am using the heavy multi-strand copper |

|

|

Return to top of page · Post #: 10 · Written at 7:45:55 PM on 11 July 2013.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

I'm using tin/lead resin-core solder. A dab from a flux pen seems to help the spread of heat on old solder, I guess by getting the tip to start sinking in and increasing the contact area. |

|

|

Return to top of page · Post #: 11 · Written at 8:22:48 PM on 11 July 2013.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6929 |

|

Anyway, the amount of heat sinking into the copper wire is proving to add significant time to the contact between iron and lug. |

|

|

Return to top of page · Post #: 12 · Written at 8:57:29 PM on 11 July 2013.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

Yes, but with thick multistrand, "tinning" soaks up quite a weight of solder and you can end up with stiff, thick end that won't go through a lug hole. Several of those lugs have more than one wire or lead connected, so re-flowing the joint for another connection (say replacing a component) takes another heavy dose of heat. |

|

|

Return to top of page · Post #: 13 · Written at 10:16:24 PM on 11 July 2013.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6929 |

|

If there's no room in the lug hole due to other wire or pig tails in it, I simply solder across the lug making sure it's a good clean joint. |

|

|

Return to top of page · Post #: 14 · Written at 10:46:23 AM on 16 August 2013.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

I think I've fallen in love with 1mm copper wire and spaghetti tubing.  Maven |

|

|

« Back ·

1 ·

Next »

|

|

|

You need to be a member to post comments on this forum.

|

|

Sign In

Vintage Radio and Television is proudly brought to you by an era where things were built with pride and made to last.

DISCLAIMER: Valve radios and televisions contain voltages that can deliver lethal shocks. You should not attempt to work on a valve radio or other electrical appliances unless you know exactly what you are doing and have gained some experience with electronics and working around high voltages. The owner, administrators and staff of Vintage Radio & Television will accept no liability for any damage, injury or loss of life that comes as a result of your use or mis-use of information on this website. Please read our Safety Warning before using this website.

WARNING: Under no circumstances should you ever apply power to a vintage radio, television or other electrical appliance you have acquired without first having it checked and serviced by an experienced person. Also, at no time should any appliance be connected to an electricity supply if the power cord is damaged. If in doubt, do not apply power.

Shintara - Keepin' It Real · VileSilencer - Maintain The Rage