Workshops, Tools and Test Equipment

Forum home - Go back to Workshops, Tools and Test Equipment

|

My workshop Fred Lever

|

|

|

Return to top of page · Post #: 31 · Written at 3:23:34 PM on 18 February 2020.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6905 |

|

And Boeing is going the same way! "Outsourcing" their IP, design and production. |

|

|

Return to top of page · Post #: 32 · Written at 11:27:00 PM on 18 February 2020.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7585 |

|

It shows with the latest 737. Even if that plane does make it back into the sky, I certainly will not be getting on board. Pushing the newer, heavier engines forward and expecting a computer programme to compensate for it was madness. Why didn't Boeing keep the engines where they were on the previous model and install taller landing gear to keep the engines off the runway? ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 33 · Written at 8:25:23 AM on 19 February 2020.

|

|

|

|

Location: Linton, VIC

Member since 30 December 2016 Member #: 2028 Postcount: 472 |

|

Why didn't Boeing keep their original engine configuration? |

|

|

Return to top of page · Post #: 34 · Written at 8:42:28 AM on 19 February 2020.

|

|

|

|

Location: Toongabbie, NSW

Member since 19 November 2015 Member #: 1828 Postcount: 1390 |

|

Selling a commercial aircraft that flies like a military design is madness. |

|

|

Return to top of page · Post #: 35 · Written at 6:00:09 PM on 19 February 2020.

|

|

|

|

Location: Belrose, NSW

Member since 31 December 2015 Member #: 1844 Postcount: 2674 |

|

They needed the new engines to compete with Airbus on running costs, i.e. fuel efficiency. High bypass turbofans have to be larger diameter. |

|

|

Return to top of page · Post #: 36 · Written at 7:00:31 PM on 19 February 2020.

|

|

|

|

Location: NSW

Member since 10 June 2010 Member #: 681 Postcount: 1386 |

|

Another reason was that the Airbus competitor to the 737 Max was designed with engine change only, was because it was then deemed to be the same plane as its predecessor. This meant that the aircrew could then be trained on simulator only, reducing costs for the airlines. |

|

|

Return to top of page · Post #: 37 · Written at 7:23:24 PM on 19 February 2020.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7585 |

|

Fred, your first sentence reminded me of something. When the B2 stealth bomber was being devised, the Americans wanted to be sure that no radar system anywhere in the world could pick up its approach. This is why it looks a bit like a hang glider after Christmas lunch. No tail fin, no exposed engines, etc, just a big pair of wings. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 38 · Written at 8:27:59 PM on 19 February 2020.

|

|

|

|

Location: Linton, VIC

Member since 30 December 2016 Member #: 2028 Postcount: 472 |

|

Could I just add that we are doubly lucky they are on our side? |

|

|

Return to top of page · Post #: 39 · Written at 9:16:42 PM on 19 February 2020.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7585 |

|

Well, it is true that teamwork is a two way street. They probably wonder about it a bit during naval exercises when their destroyers are in search of our submarines only to end up being told that our sub is under the keels of their ships. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 40 · Written at 6:27:07 AM on 23 March 2020.

|

|

|

|

Location: Penrith, NSW

Member since 7 April 2012 Member #: 1128 Postcount: 403 |

|

Dear Fred. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ I love the smell of ozone in the morning. |

|

|

Return to top of page · Post #: 41 · Written at 4:41:56 PM on 1 April 2020.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5662 |

|

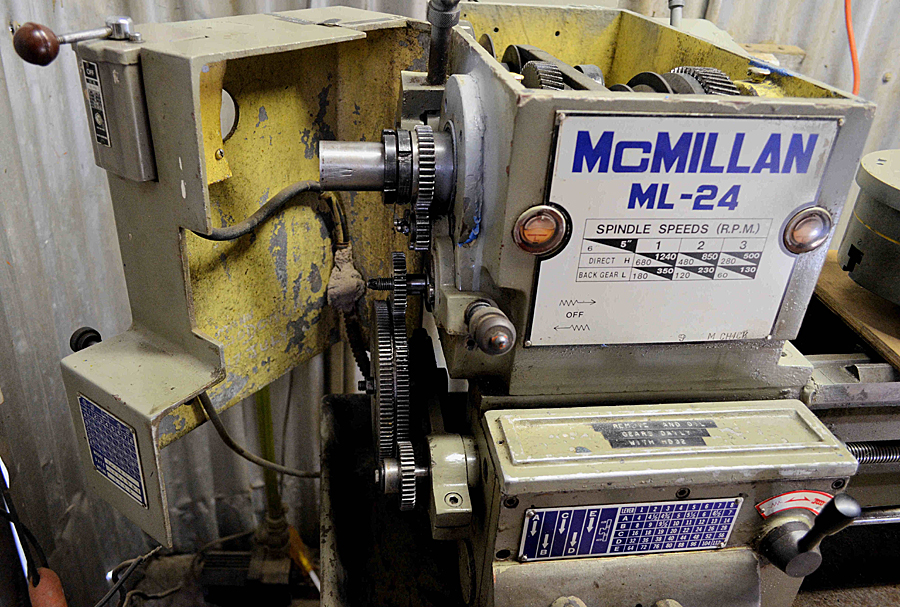

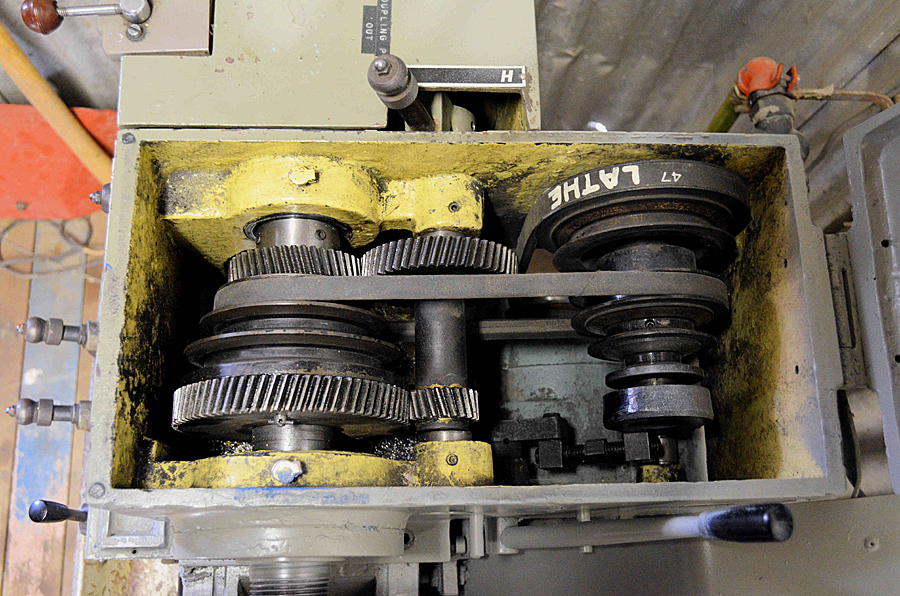

Now seeing there is no Mens Shed, meetings etc. and I am laying low as the lungs decided to chuck a wobbly (not unusual) A lot of "put off" jobs are being mowed down. Still not time to reset the engine in the fergy yet, after its little incident but it has two new rear tyres. Only got 50 years out of the last lot..   |

|

|

Return to top of page · Post #: 42 · Written at 5:40:44 PM on 1 April 2020.

|

|

|

|

Location: Toongabbie, NSW

Member since 19 November 2015 Member #: 1828 Postcount: 1390 |

|

Hi Marc, looking forward to seeing snaps. |

|

|

Return to top of page · Post #: 43 · Written at 8:45:43 PM on 1 April 2020.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5662 |

|

Yeh! One needs to be careful, there are hidden traps like where they hid the retaining grub screws, shaft exit points and the treacherous key. |

|

|

Return to top of page · Post #: 44 · Written at 9:07:01 PM on 1 April 2020.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7585 |

|

Photos uploaded to Post 41. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 45 · Written at 4:04:29 PM on 2 April 2020.

|

|

|

|

Location: Belrose, NSW

Member since 31 December 2015 Member #: 1844 Postcount: 2674 |

|

Has anyone ever rebuilt an Aussie 4 speed gearbox? I had fun with one of these about 25 years back when youngest son and I were restoring a Torana (as you do!). |

|

|

You need to be a member to post comments on this forum.

|

|

Sign In

Vintage Radio and Television is proudly brought to you by an era where things were built with pride and made to last.

DISCLAIMER: Valve radios and televisions contain voltages that can deliver lethal shocks. You should not attempt to work on a valve radio or other electrical appliances unless you know exactly what you are doing and have gained some experience with electronics and working around high voltages. The owner, administrators and staff of Vintage Radio & Television will accept no liability for any damage, injury or loss of life that comes as a result of your use or mis-use of information on this website. Please read our Safety Warning before using this website.

WARNING: Under no circumstances should you ever apply power to a vintage radio, television or other electrical appliance you have acquired without first having it checked and serviced by an experienced person. Also, at no time should any appliance be connected to an electricity supply if the power cord is damaged. If in doubt, do not apply power.

Shintara - Keepin' It Real · VileSilencer - Maintain The Rage