Workshops, Tools and Test Equipment

Forum home - Go back to Workshops, Tools and Test Equipment

|

What's your preferred bench height? And sit or stand?

|

|

|

Return to top of page · Post #: 1 · Written at 5:06:52 PM on 15 April 2014.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6929 |

|

I've reached the point where I'm ready to equip my new workshop with benches and I have to decide on the working height. |

|

|

Return to top of page · Post #: 2 · Written at 5:43:32 PM on 15 April 2014.

|

|

|

|

Location: NSW

Member since 10 June 2010 Member #: 681 Postcount: 1395 |

|

My work bench (with drill press, vise and grinder and also used for car maintenance and any other project or house hold repair that is going on) is 920mm high. So I stand or use a swivel high stool. |

|

|

Return to top of page · Post #: 3 · Written at 8:26:49 PM on 15 April 2014.

|

|

|

|

Location: Blue Mountains, NSW

Member since 10 March 2013 Member #: 1312 Postcount: 401 |

|

As with STC830, my bench is multi purpose and things get moved on or off depending on the project at hand. Being nearly three metres long I tend to spread out a bit meaning nothing is a ever at hand if I'm seated so I've always stood with a good quality rubber anti fatigue mat. My bench is 900mm, being about 5'8" this suits me just fine. |

|

|

Return to top of page · Post #: 4 · Written at 2:16:00 AM on 22 April 2014.

|

|

|

|

Location: Central Coast, NSW

Member since 18 April 2014 Member #: 1554 Postcount: 215 |

|

Opps wrong thread |

|

|

Return to top of page · Post #: 5 · Written at 11:05:36 PM on 1 May 2014.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

My main bench is a former lab counter, so about 120cm high. I use a high stool or stand, and like being able to get a good close look at something I'm working on. I also have a Workmate vice-bench that is much lower and I use that if I am doing a lot of close soldering (say a PCB) and need the stability of sitting on a chair, or drilling or sawing where I need to be above the work. |

|

|

Return to top of page · Post #: 6 · Written at 12:04:16 AM on 2 May 2014.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6929 |

|

about 120cm high |

|

|

Return to top of page · Post #: 7 · Written at 10:51:11 PM on 3 May 2014.

|

|

|

|

Location: Canberra, ACT

Member since 23 August 2012 Member #: 1208 Postcount: 587 |

|

I guess you mean 820mm? |

|

|

Return to top of page · Post #: 8 · Written at 10:02:01 PM on 16 May 2014.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6929 |

|

Thanks for the replies, folks. |

|

|

Return to top of page · Post #: 9 · Written at 9:33:43 AM on 18 May 2014.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5675 |

|

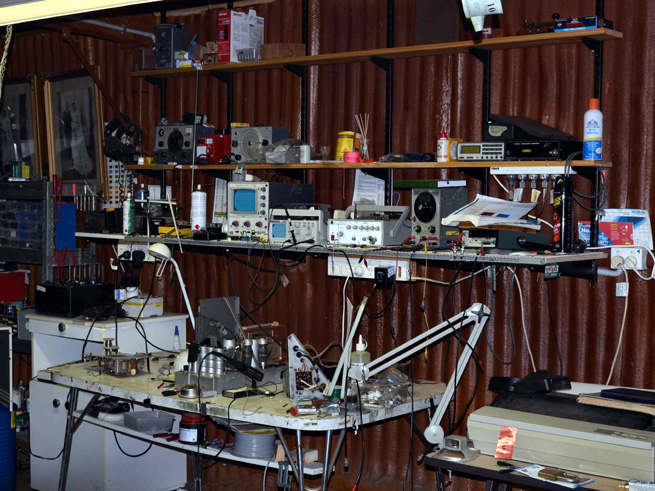

Do not forget to think outside the square: I moved house. |

|

|

Return to top of page · Post #: 10 · Written at 10:51:52 AM on 18 May 2014.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7606 |

|

Light above the bench (table) is currently a twin 85Watt, eight feet long. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 11 · Written at 5:10:14 PM on 18 May 2014.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6929 |

|

I can take photo's if anyone is interested |

|

|

Return to top of page · Post #: 12 · Written at 10:11:24 PM on 18 May 2014.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5675 |

|

Do note: This is a Farm that has always done a sprinkling of outside work and and I will resort to a wide variety of things; Hence some of the heavy toys.     The lathe & drill press in there situation, there is a 1920's Marelli ceiling fan above these that ticks over 24/7 to stop moisture forming on them. So far so good, with the right spray & cloths over them when not used. No rust new1982. That hospital cabinet with the Collaro turntable from the Philips. The bench, noting my comment for keeping it small The envelope storage for small physical sized caps & resistances. |

|

|

Return to top of page · Post #: 13 · Written at 4:55:50 PM on 19 May 2014.

|

|

|

|

Location: Tamworth, NSW

Member since 6 April 2012 Member #: 1126 Postcount: 472 |

|

My bench is 910mm and I generally sit when doing repairs. |

|

|

Return to top of page · Post #: 14 · Written at 7:33:54 PM on 19 May 2014.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7606 |

|

It's probably time I took a couple of photos of my setup. It's not exactly impressive nor it is commonly used as I do most quick restorations in the kitchen. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 15 · Written at 7:51:06 PM on 19 May 2014.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6929 |

|

Thanks for the photos Marcc. That looks to be an old kitchen table pressed into service as your bench, so I take it you prefer to work seated rather than standing? |

|

|

You need to be a member to post comments on this forum.

|

|

Sign In

Vintage Radio and Television is proudly brought to you by an era where things were built with pride and made to last.

DISCLAIMER: Valve radios and televisions contain voltages that can deliver lethal shocks. You should not attempt to work on a valve radio or other electrical appliances unless you know exactly what you are doing and have gained some experience with electronics and working around high voltages. The owner, administrators and staff of Vintage Radio & Television will accept no liability for any damage, injury or loss of life that comes as a result of your use or mis-use of information on this website. Please read our Safety Warning before using this website.

WARNING: Under no circumstances should you ever apply power to a vintage radio, television or other electrical appliance you have acquired without first having it checked and serviced by an experienced person. Also, at no time should any appliance be connected to an electricity supply if the power cord is damaged. If in doubt, do not apply power.

Shintara - Keepin' It Real · VileSilencer - Maintain The Rage