General Discussion

Forum home - Go back to General discussion

|

My Latest project AWA Big Brother Wooden Set

|

|

|

Return to top of page · Post #: 31 · Written at 11:34:31 PM on 10 November 2019.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5256 |

|

In review I do make a point of salvaging speaker transformers. One always looks forward to betting on Kriesler sets & one HMV type, the former being one of the two in eight (or worse) irrespective of model, that won't have a dud speaker transformer. |

|

|

Return to top of page · Post #: 32 · Written at 9:28:14 PM on 12 November 2019.

|

|

|

|

Location: Latham, ACT

Member since 21 February 2015 Member #: 1705 Postcount: 2156 |

|

Well today I rang the speaker hospital and they had only just finished rebuilding mine. They were able to demonstrate it over the phone . They picked a nice little ditty from the 30s and it sounded awesome. |

|

|

Return to top of page · Post #: 33 · Written at 1:05:32 AM on 16 November 2019.

|

|

|

|

Location: Latham, ACT

Member since 21 February 2015 Member #: 1705 Postcount: 2156 |

|

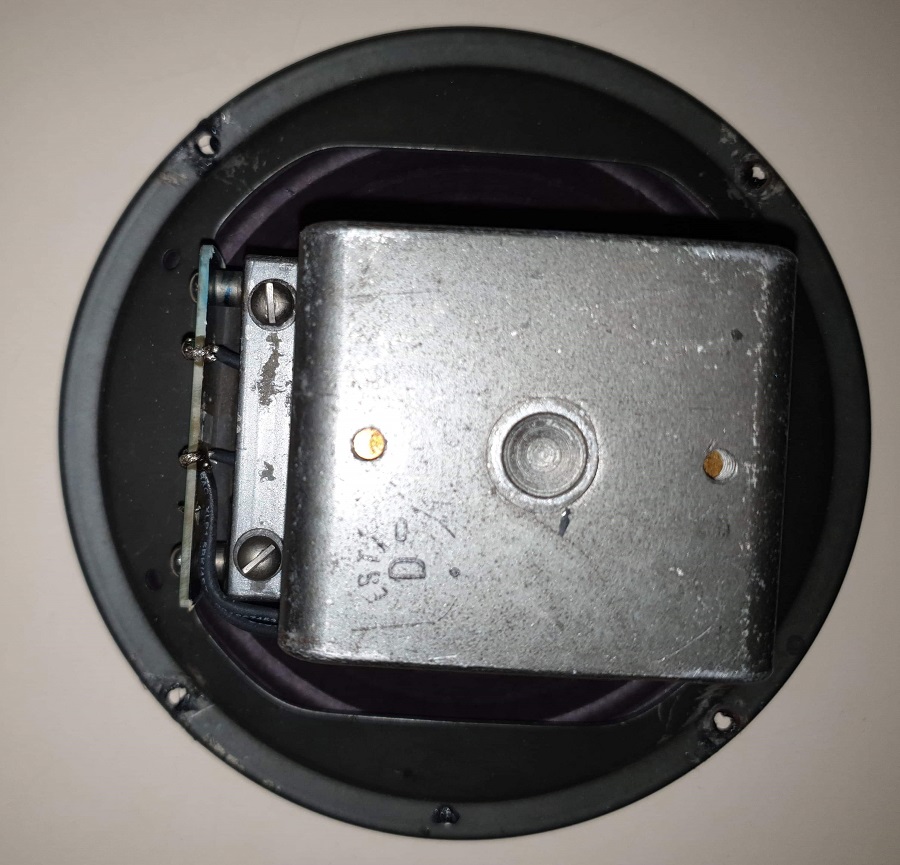

Well the speaker has arrived back at my home and is ready to be rewired back into the old set. Am I impressed, yes I am. I might remind you that this is a situation where I paid a professional for his time and that professional needs to pay his rent.   |

|

|

Return to top of page · Post #: 34 · Written at 7:30:46 PM on 16 November 2019.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7304 |

|

Photos uploaded to Post 33. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 35 · Written at 11:02:36 PM on 16 November 2019.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5256 |

|

There are the odd jobs you do buck-pass especially when you have not got the equipment to do the job, or a better one. I could have dismantled the tractors cylinder head & lapped the valves.. but no! |

|

|

Return to top of page · Post #: 36 · Written at 8:39:52 AM on 17 November 2019.

|

|

|

|

Location: Toongabbie, NSW

Member since 19 November 2015 Member #: 1828 Postcount: 1250 |

|

Agree completely Marc, the last head I overhauled included clean, crack test, valve guides, bigger seats, bigger valves, machine deck for high compression, crack test again, bush and reface rockers, new shafts, open up chambers and ports ect. All done lovingly by hand over a couple of months with Mill, Press, Grinder and Lathe. |

|

|

Return to top of page · Post #: 37 · Written at 9:17:33 AM on 17 November 2019.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5256 |

|

I get practice: The MII Zephyr has not had the head off since it blew it in 1983 & it is a first life motor that has done over 110,000 miles. Worst I have seen, (abt 2years ago) caused by people not using corrosion inhibitor was a poorly maintained MF35. I had onlooking at it & listening to it run: Decided that the head gasket was gone & it had around $1000 worth of issues without labour. So it was bought a lot cheaper than it would have been in good order. |

|

|

Return to top of page · Post #: 38 · Written at 11:50:50 AM on 18 November 2019.

|

|

|

|

Location: Toongabbie, NSW

Member since 19 November 2015 Member #: 1828 Postcount: 1250 |

|

Apologies to Carl for hi-jacking the thread with old guys comparing mechanical disasters!!!! |

|

|

Return to top of page · Post #: 39 · Written at 4:11:53 PM on 18 November 2019.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5256 |

|

I note a sheen across the corrugations, I do wonder if they are doing something similar to what do? |

|

|

Return to top of page · Post #: 40 · Written at 9:18:58 PM on 18 November 2019.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7304 |

|

...we need an off topic forum where we can enthrall people with our mechanical dare-ing do ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 41 · Written at 10:32:23 PM on 18 November 2019.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5256 |

|

So true: That's what you get when you post in this non specific area. It often gets very interesting by meandering off on many tangents. |

|

|

Return to top of page · Post #: 42 · Written at 10:33:16 PM on 18 November 2019.

|

|

|

|

Location: Albury, NSW

Member since 1 May 2016 Member #: 1919 Postcount: 2048 |

|

It does not look like nitro. |

|

|

Return to top of page · Post #: 43 · Written at 1:45:39 AM on 19 November 2019.

|

|

|

|

Location: Latham, ACT

Member since 21 February 2015 Member #: 1705 Postcount: 2156 |

|

It's ok guys I'm happy to have a bit of friendly banter lol. |

|

|

Return to top of page · Post #: 44 · Written at 10:43:45 PM on 19 November 2019.

|

|

|

|

Location: Latham, ACT

Member since 21 February 2015 Member #: 1705 Postcount: 2156 |

|

Well I have to say I'm pretty damned happy with this set now. It's a pretty good example of a set with a lot of stupid mistakes in it. Take for example those silly green and yellow terminals in the back. I decided after all other things had failed to get rid of the horrible distortion that was present to just remove the jumper between those terminals. Three things could happen (1) it would stop working (2) it would sound worse or (3) it would sound better. Well it was number three, not only did the volume go to full strength but the distortion disappeared as well. For the life of me I don't understand how anyone could have thought that was good for this set. Now it sings at full volume and is a real show stopper. I also installed a 500k volume switchpot and replaced the 500k tone control pot and now all I have to do is tidy it up in readiness for its restored cabinet . |

|

|

Return to top of page · Post #: 45 · Written at 11:21:48 PM on 20 November 2019.

|

|

|

|

Location: Hill Top, NSW

Member since 18 September 2015 Member #: 1801 Postcount: 2015 |

|

That is the point I made back in Post #24. |

|

|

You need to be a member to post comments on this forum.

|

|

Sign In

Vintage Radio and Television is proudly brought to you by an era where things were built with pride and made to last.

DISCLAIMER: Valve radios and televisions contain voltages that can deliver lethal shocks. You should not attempt to work on a valve radio or other electrical appliances unless you know exactly what you are doing and have gained some experience with electronics and working around high voltages. The owner, administrators and staff of Vintage Radio & Television will accept no liability for any damage, injury or loss of life that comes as a result of your use or mis-use of information on this website. Please read our Safety Warning before using this website.

WARNING: Under no circumstances should you ever apply power to a vintage radio, television or other electrical appliance you have acquired without first having it checked and serviced by an experienced person. Also, at no time should any appliance be connected to an electricity supply if the power cord is damaged. If in doubt, do not apply power.

Shintara - Keepin' It Real · VileSilencer - Maintain The Rage