General Discussion

Forum home - Go back to General discussion

|

3D Printers and radio repairs

|

|

|

« Back ·

1 ·

Next »

|

|

|

Return to top of page · Post #: 1 · Written at 8:44:34 AM on 3 April 2017.

|

|

|

|

Location: Newcomb, VIC

Member since 24 May 2015 Member #: 1750 Postcount: 7 |

|

Hello all,      |

|

|

Return to top of page · Post #: 2 · Written at 6:44:06 AM on 4 April 2017.

|

|

|

|

Location: Latham, ACT

Member since 21 February 2015 Member #: 1705 Postcount: 2174 |

|

So what process did you use to smooth the printed items . I will need to spray mine with ivory paint . Mine is the Healing L502E discussion in this group. |

|

|

Return to top of page · Post #: 3 · Written at 5:18:19 PM on 4 April 2017.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6761 |

|

Very nice work, Bernie. |

|

|

Return to top of page · Post #: 4 · Written at 5:56:57 PM on 4 April 2017.

|

|

|

|

Location: Tamworth, NSW

Member since 6 April 2012 Member #: 1126 Postcount: 466 |

|

Wow |

|

|

Return to top of page · Post #: 5 · Written at 7:07:46 PM on 4 April 2017.

|

|

|

|

Location: Hill Top, NSW

Member since 18 September 2015 Member #: 1801 Postcount: 2078 |

|

Nice. I also have STC radios with broken cases and grills. They can break at the slightest touch. |

|

|

Return to top of page · Post #: 6 · Written at 8:33:50 AM on 5 April 2017.

|

|

|

|

Location: NSW

Member since 10 June 2010 Member #: 681 Postcount: 1301 |

|

While visiting Sutherland Shire Library at Sutherland recently I noticed that they have a small display case with 3D printed items. Most have the |

|

|

Return to top of page · Post #: 7 · Written at 2:41:40 PM on 6 April 2017.

|

|

|

|

Location: NSW

Member since 10 June 2010 Member #: 681 Postcount: 1301 |

|

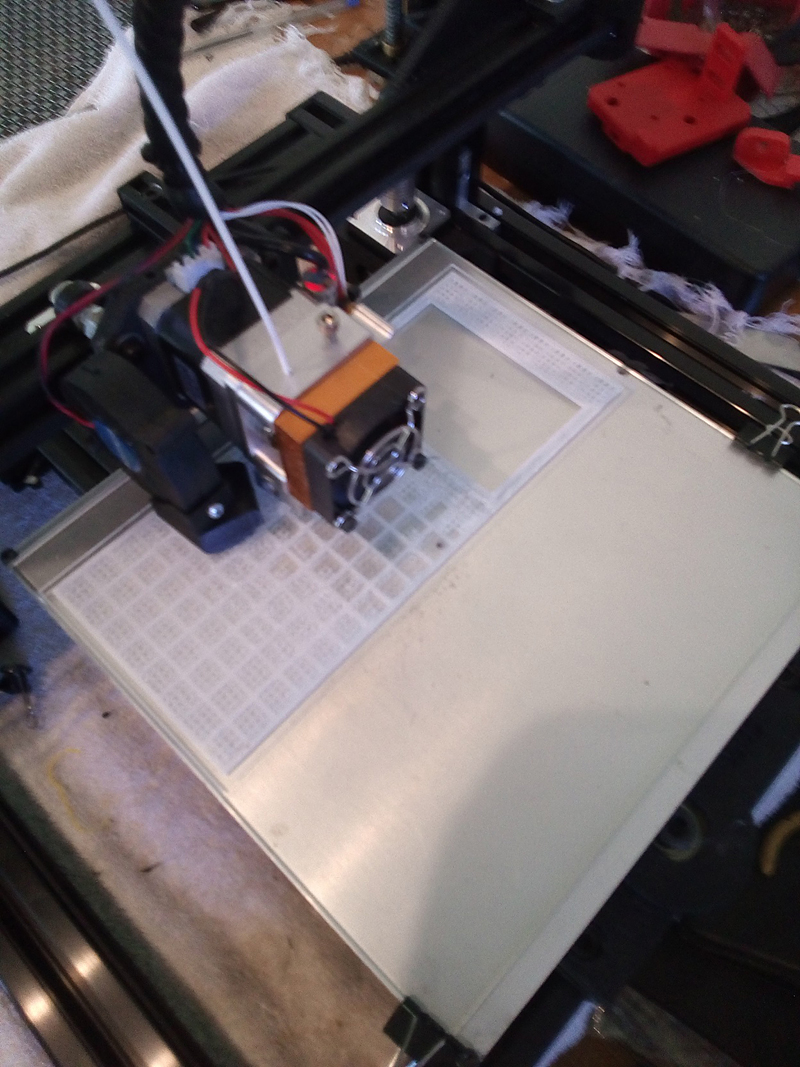

I had occasion to call into Sutherland Library again today, and was lucky enough to see their 3D printer in action under the care of it operator. |

|

|

Return to top of page · Post #: 8 · Written at 7:30:41 AM on 10 April 2017.

|

|

|

|

Location: Newcomb, VIC

Member since 24 May 2015 Member #: 1750 Postcount: 7 |

|

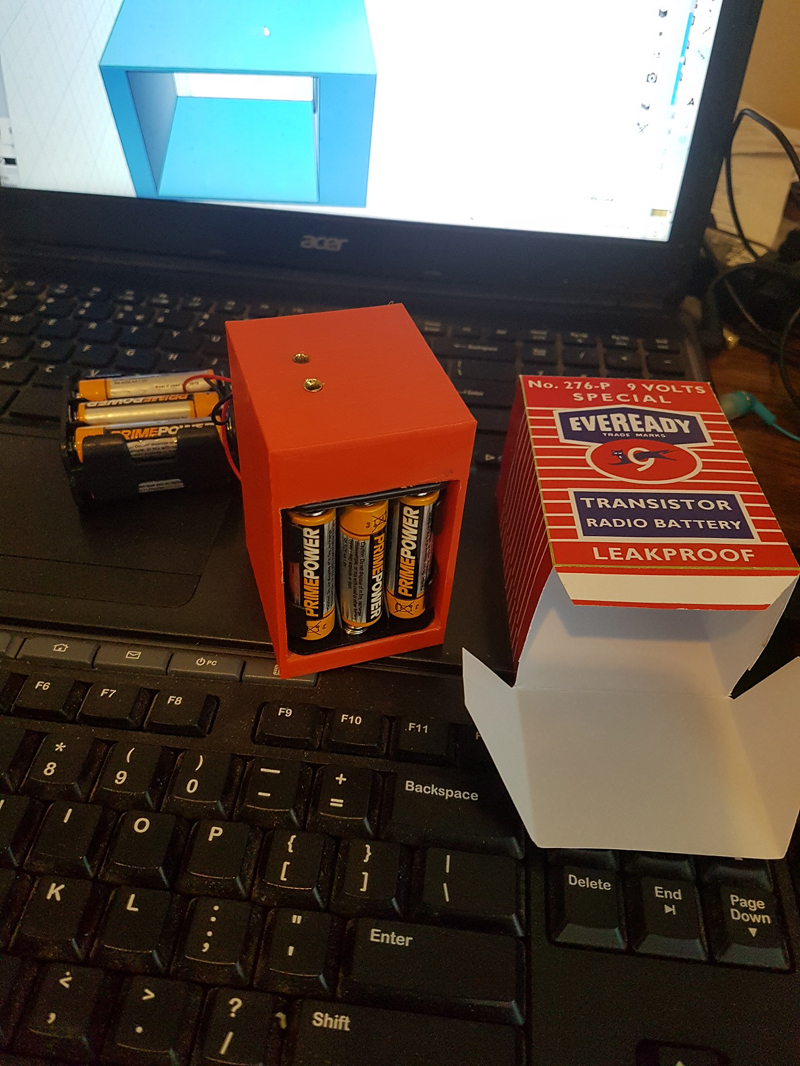

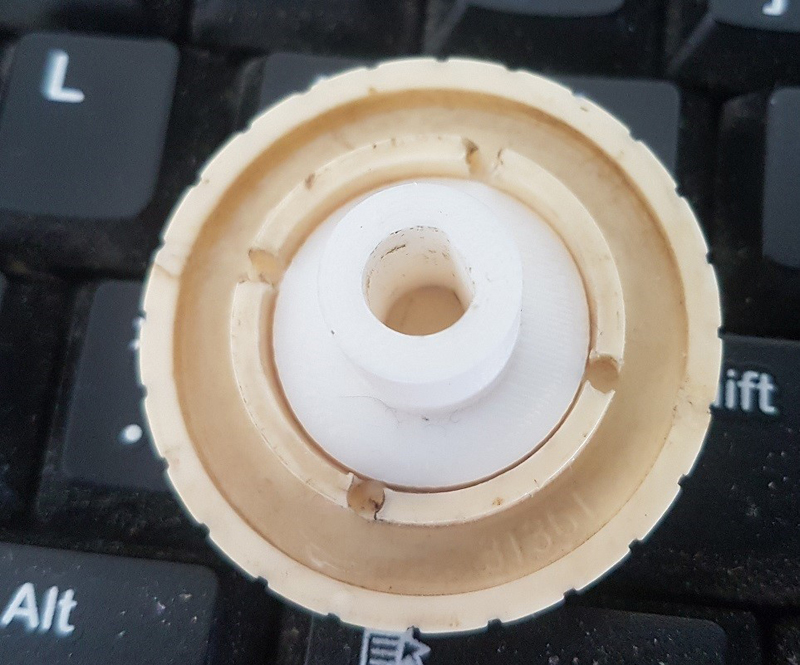

Thanks for the comments everyone!   Thanks again for the feedback cheers, Bernie |

|

|

Return to top of page · Post #: 9 · Written at 8:37:23 PM on 10 April 2017.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7395 |

|

Photos uploaded to Post 8. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 10 · Written at 11:38:07 PM on 10 April 2017.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6761 |

|

Nice trick with the knobs. |

|

|

Return to top of page · Post #: 11 · Written at 8:21:28 AM on 11 April 2017.

|

|

|

|

Location: NSW

Member since 10 June 2010 Member #: 681 Postcount: 1301 |

|

"Sadly Sutherland shire is a long way from Geelong.." |

|

|

« Back ·

1 ·

Next »

|

|

|

You need to be a member to post comments on this forum.

|

|

Sign In

Vintage Radio and Television is proudly brought to you by an era where things were built with pride and made to last.

DISCLAIMER: Valve radios and televisions contain voltages that can deliver lethal shocks. You should not attempt to work on a valve radio or other electrical appliances unless you know exactly what you are doing and have gained some experience with electronics and working around high voltages. The owner, administrators and staff of Vintage Radio & Television will accept no liability for any damage, injury or loss of life that comes as a result of your use or mis-use of information on this website. Please read our Safety Warning before using this website.

WARNING: Under no circumstances should you ever apply power to a vintage radio, television or other electrical appliance you have acquired without first having it checked and serviced by an experienced person. Also, at no time should any appliance be connected to an electricity supply if the power cord is damaged. If in doubt, do not apply power.

Shintara - Keepin' It Real · VileSilencer - Maintain The Rage