General Discussion

Forum home - Go back to General discussion

|

Healing L502E

|

|

|

« Back ·

1 ·

Next »

|

|

|

Return to top of page · Post #: 1 · Written at 10:53:55 AM on 11 February 2017.

|

|

|

|

Location: Latham, ACT

Member since 21 February 2015 Member #: 1705 Postcount: 2216 |

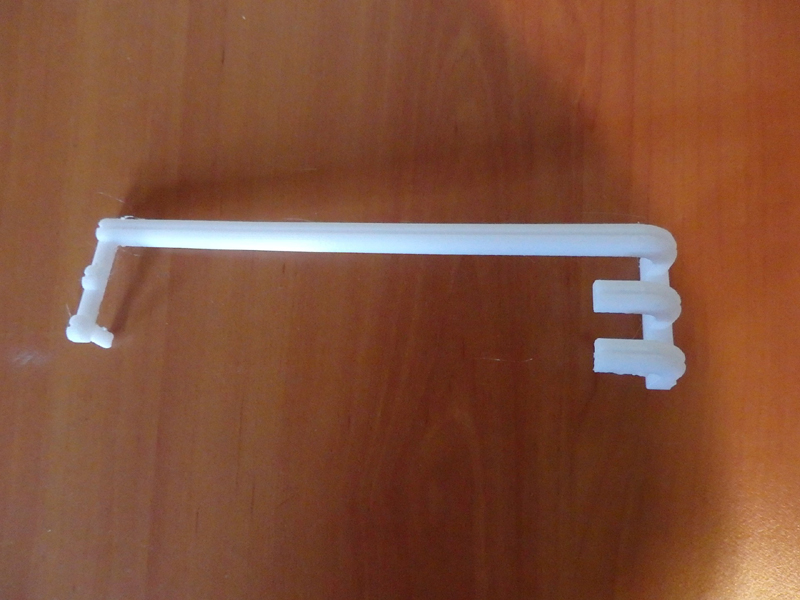

|

I have two of these sets in fairly reasonable condition except for the Grills and two missing Knobs. I have sent one of the grills and a knob to a friend that has offered to 3D print some for me. I will be posting before and after photos so you can see if its feasible. Comments welcome.    |

|

|

Return to top of page · Post #: 2 · Written at 11:39:17 AM on 11 February 2017.

|

|

|

|

Location: Albury, NSW

Member since 1 May 2016 Member #: 1919 Postcount: 2048 |

|

Hi there, |

|

|

Return to top of page · Post #: 3 · Written at 1:28:09 PM on 11 February 2017.

|

|

|

|

Location: Latham, ACT

Member since 21 February 2015 Member #: 1705 Postcount: 2216 |

|

Yes I think its the go. I am thinking of learning how to do this as I can see its probably going to be useful. |

|

|

Return to top of page · Post #: 4 · Written at 10:46:07 PM on 20 February 2017.

|

|

|

|

Location: Albury, NSW

Member since 1 May 2016 Member #: 1919 Postcount: 2048 |

|

Carl, |

|

|

Return to top of page · Post #: 5 · Written at 7:18:22 AM on 25 February 2017.

|

|

|

|

Location: Latham, ACT

Member since 21 February 2015 Member #: 1705 Postcount: 2216 |

|

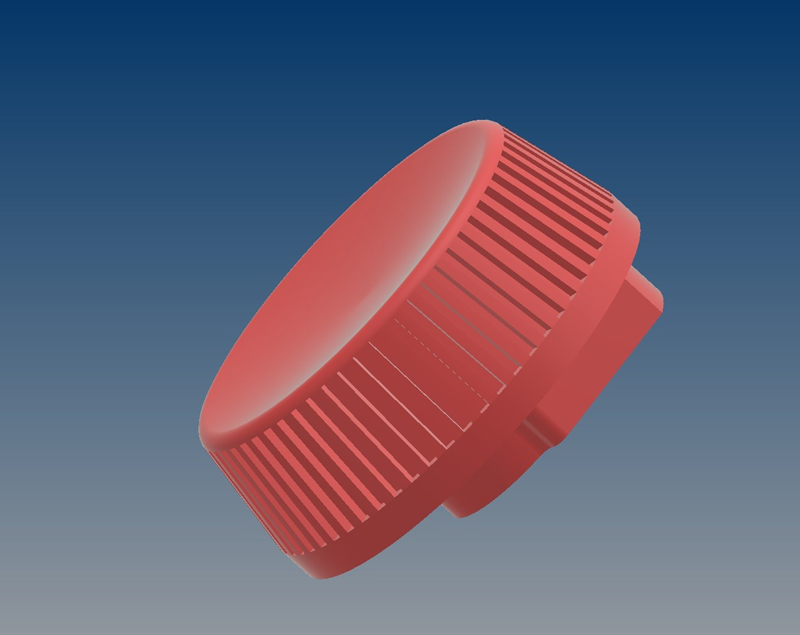

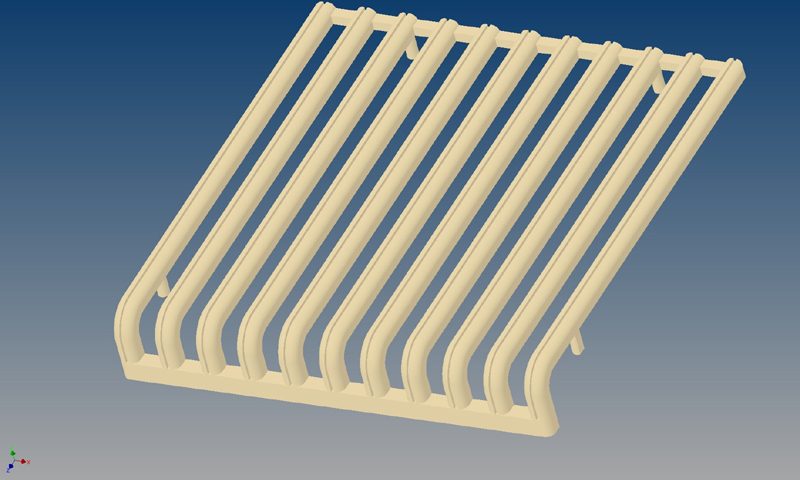

Well people I have two new knobs and a cad design for the grills , they look pretty cool at the moment. Pics on the way.    |

|

|

Return to top of page · Post #: 6 · Written at 9:39:35 AM on 26 February 2017.

|

|

|

|

Location: Wangaratta, VIC

Member since 21 February 2009 Member #: 438 Postcount: 5590 |

|

Quite some time ago, I did make comment on the American Radio Forum that a particular horrid shaped bit of die casting that had done what it does, could be cut out with a CNC or printed. |

|

|

Return to top of page · Post #: 7 · Written at 12:36:12 PM on 26 February 2017.

|

|

|

|

Location: Albury, NSW

Member since 1 May 2016 Member #: 1919 Postcount: 2048 |

|

Should be happy with that. |

|

|

Return to top of page · Post #: 8 · Written at 7:22:46 PM on 22 March 2017.

|

|

|

|

Location: Latham, ACT

Member since 21 February 2015 Member #: 1705 Postcount: 2216 |

|

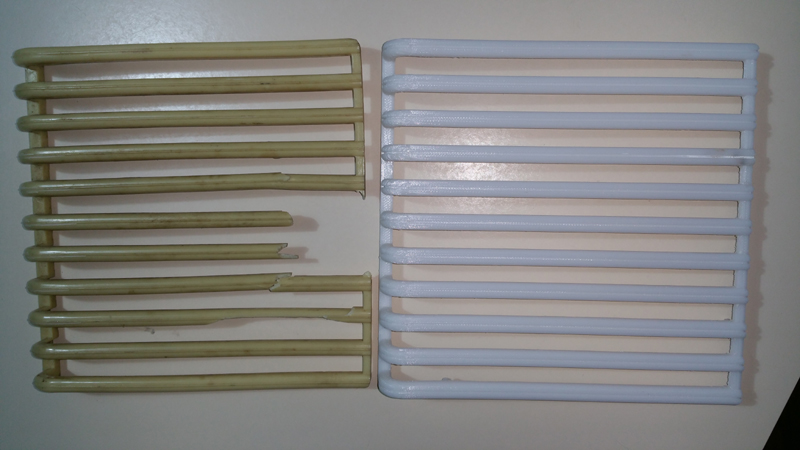

Well guys I do have the grilles and knobs in my hot little hands.    |

|

|

Return to top of page · Post #: 9 · Written at 9:53:16 PM on 22 March 2017.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7548 |

|

There's no doubt that the printing is quite accurate though how will you end up with a smooth finish on the items? ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 10 · Written at 10:50:03 PM on 22 March 2017.

|

|

|

|

Location: Sydney, NSW

Member since 28 January 2011 Member #: 823 Postcount: 6882 |

|

If it were me, for a smooth smooth finish I would try the lightly lubricated graduated wet and dry technique I use to recover faded plastic cases and cloudy dial lenses, followed by Autosol liquid metal polish to add the lustre and I would use a practice piece first. |

|

|

Return to top of page · Post #: 11 · Written at 11:34:50 AM on 23 March 2017.

|

|

|

|

Location: Adelaide, SA

Member since 27 February 2010 Member #: 630 Postcount: 398 |

|

They look like a very good start. Just need to "Finish" them up a bit. The only comment is the colour of the Grill, Need to find some Cream / Antique White paint that will stick to it. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ Valve radios, They just don't make them like they used to |

|

|

Return to top of page · Post #: 12 · Written at 1:35:48 PM on 23 March 2017.

|

|

|

|

Location: NSW

Member since 10 June 2010 Member #: 681 Postcount: 1370 |

|

Dy-Mark make Plastic Primer for priming plastics such as polypropylene, PVC & vinyl, but not suitable for polyethylene. I have a can of this and it provides good adhesion for the right plastics. |

|

|

Return to top of page · Post #: 13 · Written at 4:46:53 PM on 23 March 2017.

|

|

|

|

Administrator

Location: Naremburn, NSW

Member since 15 November 2005 Member #: 1 Postcount: 7548 |

|

Spray putty. ‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾‾ A valve a day keeps the transistor away... |

|

|

Return to top of page · Post #: 14 · Written at 7:57:47 AM on 28 March 2017.

|

|

|

|

Location: NSW

Member since 10 June 2010 Member #: 681 Postcount: 1370 |

|

That's the stuff - AutoOne have it on special at the moment in 400g aerosol cans, along with various other primers including an all surface primer that might suit 3D print plastic. |

|

|

« Back ·

1 ·

Next »

|

|

|

You need to be a member to post comments on this forum.

|

|

Sign In

Vintage Radio and Television is proudly brought to you by an era where things were built with pride and made to last.

DISCLAIMER: Valve radios and televisions contain voltages that can deliver lethal shocks. You should not attempt to work on a valve radio or other electrical appliances unless you know exactly what you are doing and have gained some experience with electronics and working around high voltages. The owner, administrators and staff of Vintage Radio & Television will accept no liability for any damage, injury or loss of life that comes as a result of your use or mis-use of information on this website. Please read our Safety Warning before using this website.

WARNING: Under no circumstances should you ever apply power to a vintage radio, television or other electrical appliance you have acquired without first having it checked and serviced by an experienced person. Also, at no time should any appliance be connected to an electricity supply if the power cord is damaged. If in doubt, do not apply power.

Shintara - Keepin' It Real · VileSilencer - Maintain The Rage